Honda Accord: Piston Installation

Honda Accord: Piston Installation

If the Crankshaft is Already Installed

1. Set the crankshaft to bottom dead center (BDC) for each cylinder as its piston is installed.

2. Remove the connecting rod caps, then install the ring compressor, and check that the bearing is securely in place.

3. Apply new engine oil to the piston, the inside of the ring compressor, and the cylinder bore, then attach the ring compressor to the piston/connecting rod assembly.

4. Position the mark (A) to face the cam chain side of the engine block.

5. Position the piston in the cylinder, and tap it in using the wooden handle of a hammer (A).

Push down on the ring compressor (B) to prevent the rings from expanding before entering the cylinder bore.

8. Stop after the ring compressor pops free, and check the connecting rod-to-rod journal alignment before pushing the piston into place.

7. Check the connecting rod bearing clearance with plastigage (see page 7-9).

8. Inspect the connecting rod bolts (see page 7-28).

9. Apply new engine oil to the bolt threads, then install the connecting rod caps with bearings. Torque the bolts to 41 N-m (4.2 kgfm, 30 Ibf-ft).

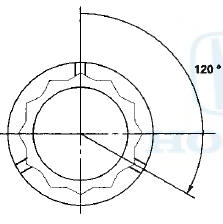

10. Tighten the connecting rod bolts an additional 120 Р’В°.

NOTE: Remove the connecting rod bolt if you tightened it beyond the specified angle, and go back to step 8 of the procedure. Do not loosen it back to the specified angle.

If the Crankshaft is Not Installed

1. Remove the connecting rod caps, then install the ring compressor, and check that the bearing is securely in place.

2. Apply new engine oil to the piston, the inside of the ring compressor, and the cylinder bore, then attach the ring compressor to the piston/connecting rod assembly.

3. Position the mark (A) to face the cam chain side of the engine block.

4. Position the piston in the cylinder, and tap it in using the wooden handle of a hammer (A).

Push down on the ring compressor (B) to prevent the rings from expanding before entering the cylinder bore.

5. Position all pistons at top dead center (TDC).

Piston Ring Replacement

Piston Ring Replacement

1. Remove the piston from the engine block (see page

7-14).

2. Using a ring expander (A), remove the old piston

rings (B).

3. Clean all ring grooves thoroughly with a squared-off

broken ring ...

Connecting Rod Bolt Inspection

Connecting Rod Bolt Inspection

1. Measure the diameter of each connecting rod bolt at

point A and point B.

2. Calculate the difference in diameter between point A

and point B.

Point A-”Point B = Difference in Diameter

D ...

See also:

Selecting a Memorized Position

To select a memorized position, do

this:

1. Make sure the parking brake is set

and the shift lever is in Park

(automatic).

2. Press the desired memory button

(1 or 2) until you hear a beep ...

Compass

EX-L and all V6 without navigation

system ...