Honda Accord: Intermediate Shaft Reassembly

Honda Accord: Intermediate Shaft Reassembly

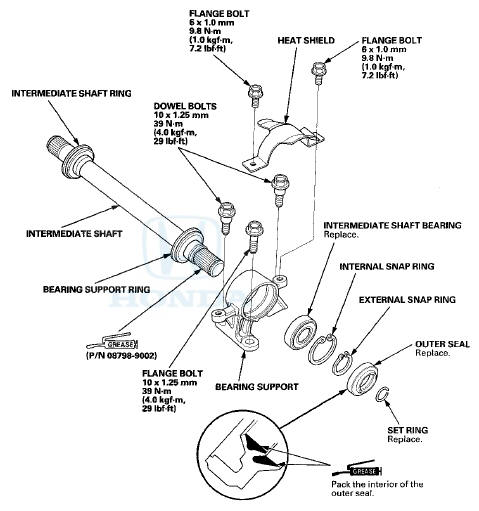

Exploded View

Special Tools Required

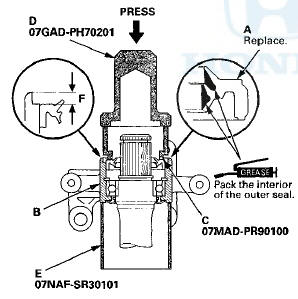

-Oil Seal Driver 07GAD-PH70201

-Half Shaft Base 07NAF-SR30101

-Attachment 52 x 55 mm 07746-0010400

-Attachment 35 mm I.D. 07746-0030400

-Driver Handle, 15 x 135L 07749-0010000

-Attachment 45 x 55 mm 07MAD-PR90100

NOTE; Refer to the Exploded View, as needed, during this procedure.

1. Clean the disassembled parts with solvent, and dry them with compressed air.

NOTE: Do not wash the rubber parts with solvent.

2. Press a new intermediate shaft bearing (A) into the bearing support (B) using the 52 x 55 mm attachment and a press.

3. Install the internal snap ring (A) into the groove (B) of the bearing support.

4. Press the intermediate snatt |A) into the shaft bearing (B) using the 35 mm attachment (C) and the press.

5. Install the external snap ring (A) into the groove of the intermediate shaft (B).

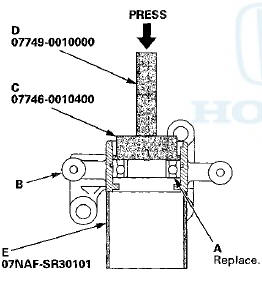

. Install a new outer seal (A) into the bearing support (B) using the 45X55 mm attachment (C), the oil seal driver (D), the half shaft base (E), and the press. Press in the seal until it is 4 В± 0.2 mm (0.16 В± 0.008 in) (F) below the surface of the bearing support end.

7. Install the heat shield (A).

Intermediate Shaft Disassembly

Intermediate Shaft Disassembly

Special Tools Required

•Half Shaft Base 07NAF-SR30101

-Oil Seal Driver, 44.5 mm 07947-SB00100

1. Remove the heat shield (A).

3. Press the intermediate shaft (A) out of the

intermediate s ...

Intermediate Shaft Installation

Intermediate Shaft Installation

1. Clean the areas where the Intermediate shaft contacts

the differential thoroughly with solvent, and dry then

with compressed air.

NOTE: Do not wash the rubber parts with solvent.

2. Install ...

See also:

To Turn Everything Off

To turn the system completely off,

press the ON/OFF button.

Keep the system completely off

for short periods only.

To keep stale air and mustiness

from collecting, you should have

the fan ru ...

Fluid Replacement

Check the reservoir (A) at regular intervals, and add the

recommended fluid as necessary. Always use Honda

Power Steering Fluid. Using any other type of power

steering fluid or automatic transmissi ...

Rocker Arm and Shaft Disassembly/Reassembly

NOTE:

- Identify each part as it is removed so that each item can be

reinstalled in its original locations,

a Inspect the rocker arm shaft and rocker arms (see page 6-83).

- I ...