Honda Accord: Connecting Rod and Crankshaft End Play Inspection

Honda Accord: Connecting Rod and Crankshaft End Play Inspection

1. Remove the oil pump (see page 8-16).

2. Remove the baffle plate (see step 8 on page 7-14).

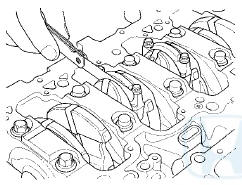

3. Measure the connecting rod end play with a feeler gauge between the connecting rod and the crankshaft.

Connecting Rod End Play

Standard (New): 0.15-0.35 mm (0.006-0.014 in)

Service Limit: 0.40 mm (0.016 in)

4. If the connecting rod end play is beyond the service limit, install a new connecting rod, and recheck. If it is still beyond the service limit replace the crankshaft (see page 7-14).

5. Push the crankshaft firmly away from the dial indicator, and zero the dial against the end of the crankshaft. Then pull the crankshaft firmly back toward the indicator; the dial reading should not exceed the service limit.

Crankshaft End Play

Standard (New): 0.10-0.35 mm (0.004- 0.014 in)

Service Limit: 0.45 mm (0.018 in)

6. If the end play is beyond the service limit, replace the thrust washers and recheck, if it is still beyond the service limit, replace the crankshaft (see page 7-14).

Crankshaft Main Bearing Replacement

Crankshaft Main Bearing Replacement

Main Bearing Clearance Inspection

1. To check the main bearing-to-journal oil clearance,

remove the lower block and the bearing halves (see

page 7-14).

2. Clean each main journal and the bearing ...

See also:

Circuit Diagram

...

Brakes

...

A FewWordsAbout Safety

Your safety, and the safety of others,

is very important. And operating this

vehicle safely is an important

responsibility.

To help you make informed

decisions about safety, we have

provide ...