Honda Accord: Cf Hinder Bore Honing

Honda Accord: Cf Hinder Bore Honing

Only a scored or scratched cylinder bore must be honed.

1. Measure the cylinder bores (see page 7-17).

If the engine block is to be reused, hone the cylinders, and remeasure the bores.

2. Remove the oil jets (see page 8-14).

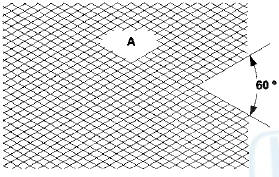

3. Hone the cylinder bores with honing oil and a fine (400 grit) stone in a 60 degree cross-hatch pattern (A).

Use only a rigid hone with 400 grit or finer stone such as Sunnen, Ammco, or equivalent. Do not use stones that are worn or broken.

4. When honing is complete, thoroughly clean the engine block of all metal particles. Wash the cylinder bores with hot soapy water, then dry and oil them immediately to prevent rusting. Never use solvent, it will only redistribute the grit on the cylinder walls.

5. If scoring or scratches are still present in the cylinder bores after honing the engine block to the service limit, rebore the engine block. Some light vertical scoring and scratching is acceptable if it is not deep enough to catch your fingernail, and does not run the full length of the bore.

6. Install the oil jets (see page 8-14).

Block and Piston inspection

Block and Piston inspection

1. Remove the crankshaft and the pistons (see page

7-14).

2. Check the piston for distortion or cracks.

3. Measure the piston diameter at a point 13 mm (0.5 in)

from the bottom of the skirt. T ...

Piston, Pin, and Confyssfeg EQC

Replacement

Piston, Pin, and Confyssfeg EQC

Replacement

Disassembly

1. Remove the piston from the engine block (see page

7-14).

2. Apply new engine oil to the piston pin snap rings (A),

and turn them in the ring grooves until the end gaps

are lined ...

See also:

Parking Brake

To apply the parking brake, pull the

lever up fully. To release it, pull up

slightly, push the button, and lower

the lever. The parking brake

indicator on the instrument panel

should go ou ...

Washer Fluid Level Switch Test

Canada models

1. Remove the right inner fender (see page 20-290).

2. Disconnect the 2P connector (A) from the washer fluid

level switch (B).

3. Remove the washer fluid level switch from the

w ...

Safety of Infants and Small Children

• Protecting Infants

An infant must be properly restrained in a rear-facing, reclining child seat

until the

infant reaches the seat maker's weight or height limit for the seat, and the

infant ...