Honda Accord: Clutch Clearance Inspection

Honda Accord: Clutch Clearance Inspection

Special Tools Required

Clutch Compressor Attachment 07ZAE-PRP0100

1. Inspect the clutch piston, the clutch discs, the clutch plates, and the clutch end-plate for wear and damage (see page 14-303), and inspect the clutch wave-plate phase difference (see page 14-304), if necessary.

2. Install the clutch piston in the clutch drum. Do not install the O-rings during inspection.

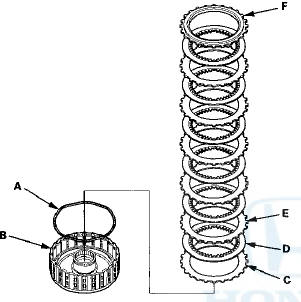

3. Install the waved spring (A) in the 1st clutch drum (B).

Install the clutch flat-plate (C), then starting with the clutch disc, alternately install the clutch discs (D) (5) and the clutch wave-plates (E) (4), then install the clutch end-plate (F) with the flat side toward the top disc.

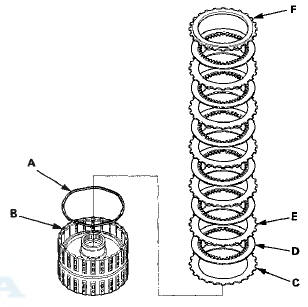

4. Install the waved spring (A) in the 2nd clutch drum (B).

Install the clutch flat-plate (C), then starting with the clutch disc, alternately install the clutch discs (D) (6) and the wave-plates (E) (5), then install the clutch end-plate (F) with the flat side toward the top disc.

5. Install the waved spring (A) in the 3rd clutch drum (B).

Install the clutch flat-plate (C), then starting with the clutch disc, alternately install the clutch discs (D) (6) and the clutch wave-plates (E) (5), then install the clutch end-plate (F) with the flat side toward the top disc.

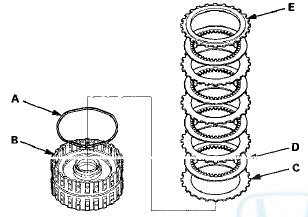

6. Install the waved spring (A) in the 4th clutch drum (B).

Starting with the clutch wave-plate, alternately install the clutch wave-plates (C) (4) and the clutch discs (D) (4), then install the clutch end-plate (E) with the flat side toward the top disc.

7. Install the waved spring (A) in the 5th clutch drum (B).

Starting with the clutch wave-plate, alternately install the clutch wave-plates (C) (4) and the clutch discs (D) (4), then install the clutch end-plate (E) with the flat side toward the top disc.

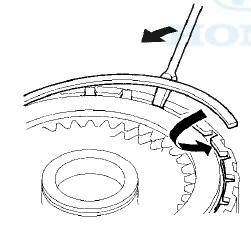

8. Install the snap ring using a screwdriver.

9. Set a dial indicator (A) on the clutch end-plate (B).

10. Zero the dial indicator with the clutch end-plate lifted up to the snap ring (C).

11. Release the clutch end-plate to lower the clutch end-plate, then put the clutch compressor attachment on the clutch end-plate (A).

12. Press the clutch compressor attachment down with 147 N (15 kgf, 33 Ibf) (B) using a force gauge, and read the dial indicator (C).

13. The dial indicator reads the clearance (D) between the clutch end-plate and the top disc (E). Take measurements in at least three places, and use the average as the actual clearance.

Clearance between Clutch End-Plate and Top Disc

Standard:

1st Clutch: 1.38-1.58 mm (0.054-0.062 in)

2nd Clutch: 1.14-1.34 mm (0.045-0.053 in)

3rd Clutch: 1.23-1.43 mm (0.048-0.056 in)

4th Clutch: 0.93-1.13 mm (0.037-0.044 in)

5th Clutch: 0.93-1.13 mm (0.037-0.044 in)

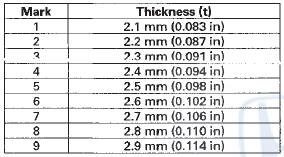

14. If the clearance is out of the standard, select a new clutch end-plate from the following table.

1ST CLUTCH END-PLATES

2ND CLUTCH END-PLATES

3RD, 4TH, and STH CLUTCH END-PLATES

15. Install a new clutch end-platef and recheck the clearance. If the thickest clutch end-plate is installed, but the clearance is still over the service limit, replace the clutch discs and the clutch plates.

Clutch Wave-plate Phase Difference

Inspection

Clutch Wave-plate Phase Difference

Inspection

1. Place the clutch wave-plate (A) on a surface plate, and

set a dial indicator (B) on the wave-plate.

2. Find the bottom (C) of a phase difference of the

wave-plate, zero the dial indicator an ...

1st, 2nd, and 3rd Clutch Reassembly

1st, 2nd, and 3rd Clutch Reassembly

Special Tools Required

Clutch Spring Compressor Set 07LAE-PX40000

NOTE: Hold the spring compressor in a vise with soft

jaws. Be careful not to damage the clutch drum.

1 Soak the clutch discs tho ...

See also:

B-CAN System Diagnosis Test Mode

1 and Test Mode 2 (without the

HDS)

Special Tools Required

MFCS (MCIC) Service Connector 07WAZ-00101 OA

Test Mode 1

Check the ECM/PCM for DTCs and troubleshoot

ECM/PCM (see p a g e 11-3) or F-CAN loss o f

communication errors first ...

Wear Indicators

The groove where the wear indicator is

located is 1/16 inch (1.6 mm) shallower than

elsewhere on the tire. If the tread has worn so

that the indicator is exposed, replace the tire.

Worn out ...

Navigation Communication Line Circuit

Troubleshooting

1. Operate the climate control system in several modes.

Is the climate control system OK?

YES-Go to step 2.

NO-Do the self-diagnostic function with the HDS (see

page 21-102) or climate control ...