Honda Accord: Valve Clearance Adjustment

Honda Accord: Valve Clearance Adjustment

Special Tools Required

. Locknut Wrench 07MAA-PR70120

. Adjuster 07MAA-PR70110

NOTE: Connect the Honda Diagnostic System (HDS) to the data link connector (DLC) and monitor the engine coolant temperature (ECT) sensor 1 with the HDS. Adjust the valve clearance only when the ECT sensor 1 temperature is less than 100 Р’В°F (38 Р’В°C).

1. Remove the cylinder head cover (see page 6-73).

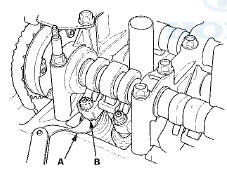

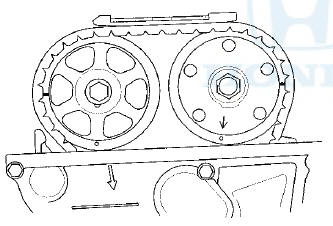

2. Set the No. 1 piston at top dead center (TDC). The punch mark (A) on the variable valve timing control (VTC) actuator and the punch mark (B) on the exhaust camshaft sprocket should be at the top. Align the TDC marks (C) on the VTC actuator and the exhaust camshaft sprocket.

3. Select the correct feeler gauge for the valve clearance you are going to check.

Valve Clearance

Intake: 0.21 - 0 . 2 5 mm (0.008-0.010 In)

Exhaust 0.25-0.29 mm (0.010-0.011 in)

4. Insert the feeler gauge (A) between the adjusting screw (B) and the end of the valve stem, and slide it back and forth; you should feel a slight amount of drag.

5. If you feel too much or too little drag, loosen the locknut with the locknut wrench and the adjuster, and turn the adjusting screw until the drag on the feeler gauge is correct.

6. Tighten the locknut to the specified torque, and recheck the clearance. Repeat the adjustment if necessary.

Specified Torque

Intake:

7 x 0.75 mm

14 N-m (1.4 kgf-m, 10 Ibfft) Apply new engine oil to the nut threads.

Exhaust:

7 x 0.75 mm

14 N-m (1.4 kgf-m, 10 Ibfft)

Apply new engine oil to the nut threads.

7. Rotate the crankshaft 180 Р’В° clockwise (camshaft pulley turns 90 Р’В°).

8. Check and, if necessary, adjust the valve clearance on the No. 3 cylinder.

9. Rotate the crankshaft 180 Р’В° clockwise (camshaft pulley turns 90 Р’В°).

10. Check and, if necessary, adjust the valve clearance on the No. 4 cylinder.

11. Rotate the crankshaft 180 Р’В° clockwise (camshaft pulley turns 90 Р’В°).

12. Check and, if necessary, adjust the valve clearance on the No. 2 cylinder.

13. Install the cylinder head cover (see page 6-74).

VTC Actuator Inspection

VTC Actuator Inspection

1. Remove the cam chain (see page 6-62).

2. Loosen the rocker arm adjusting screws (see step 2 on

page 6-81).

3. Remove the camshaft holder (see step 3 on page

6-81).

4. Remove the intake c ...

Crankshaft Pulley Removal and Installation

Crankshaft Pulley Removal and Installation

Special Tools Required

Handle, 6-25-660L 07JAB-001020B

Crankshaft Pulley Holder 07AAB-RJAA100

Socket, 19 mm 07JAA-001020A or equivalent

Removal

1 . Remove the front wheels.

2. Remove the splas ...

See also:

Countershaft Reassembly

Exploded View

*: The components of the triple cone synchro assembly.

Special Tools Required

-СћDriver Handle, 40 mm I.D. 07746-0030100

- Bearing Driver Attachment, 30 mm 07746-0030300

NOTE: R ...

Trim Removal/Installation - Pillar

Areas

Special Tools Required

KTC Trim Tool Set SOJATP2014*

*Available through the Honda Tool and

Equipment

Program; call 888-424-6857

A-Pillar Trim

SRS components are located in this area. Review the ...

Compass Zone Selection

1. Set the power mode to ON.

2. On the top screen of any audio source,

press and hold for 5

seconds.

- The display switches to the Compass

Settings screen.

3. Rotate to sele ...