Honda Accord: Crankshaft Pulley Removal and Installation

Honda Accord: Crankshaft Pulley Removal and Installation

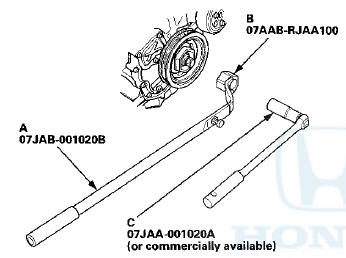

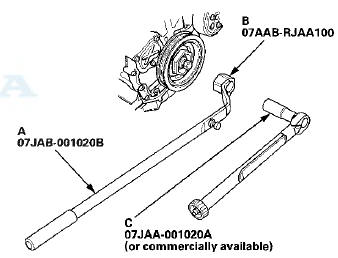

Special Tools Required

Handle, 6-25-660L 07JAB-001020B

Crankshaft Pulley Holder 07AAB-RJAA100

Socket, 19 mm 07JAA-001020A or equivalent

Removal

1 . Remove the front wheels.

2. Remove the splash shield (see step 25 on page 5-5).

3. Remove the drive belt (see page 4-30).

4. Hold the pulley with the handle, 6-25-660L (A) and the crankshaft pulley holder (B).

5. Remove the bolt with a socket, 19 mm (C) and a breaker bar, then remove the crankshaft pulley.

Installation

1. Clean the crankshaft pulley (A), the crankshaft (B), the bolt (C), and the washer (D). Lubricate with new engine oil as shown.

2. Install the crankshaft pulley, and holder the pulley with the handle (A) and the crankshaft pulley holder (B).

3. Torque the bolt to 49 N-m (5.0 kgf-m, 36 Ibf-ft) with a torque wrench and socket, 19 mm (C). Do not use an impact wrench. If the pulley bolt or crankshaft are new, torque the bolt to 177 N-m (18.0 kgf-m, 130 Ibf-ft), then remove the bolt and torque it to 49 N-m (5.0 kgf-m, 36 Ibf-ft).

4. Tighten the pulley bolt an additional 90 Р’В°.

5. Install the drive belt (see page 4-30).

6. Install the splash shield (see step 47 on page 5-20).

7. Install the front wheels.

Valve Clearance Adjustment

Valve Clearance Adjustment

Special Tools Required

. Locknut Wrench 07MAA-PR70120

. Adjuster 07MAA-PR70110

NOTE: Connect the Honda Diagnostic System (HDS) to

the data link connector (DLC) and monitor the engine

coolant temp ...

Cam Chain Removal

Cam Chain Removal

NOTE: Keep the cam chain away from magnetic fields.

1. Remove the front wheels.

2. Remove the splash shield (see step 25 on page 5-5).

3. Remove the drive belt (see page 4-30).

4. Remove t ...

See also:

Dashboard Side Vent

Removal/Installation

Special Tools Required

KTC Trim Tool Set SOJATP2014*

* Available through the Honda Tool and

Equipment

Program; call 888-424-6857

NOTE;

- Take care not to scratch the dashboard or the related

p ...

Outside Air Temperature indicator

Calibration

NOTE: To test the outside air temperature sensor (see

page 21-185).

Description

The outside air temperature sensor is located behind the

center of the front bumper. The gauge control module

uses ...