Honda Accord: Countershaft Disassembly, Inspection,

and Reassembly

Honda Accord: Countershaft Disassembly, Inspection,

and Reassembly

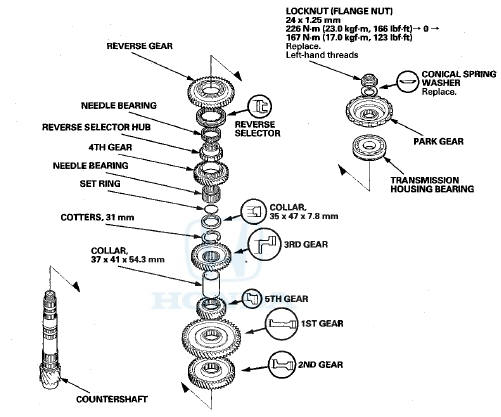

1. Inspect the needle bearings for galling and rough movement.

2. Inspect the splines for excessive wear and damage.

3. Check the shaft bearing surface for scoring and excessive wear.

4. Lubricate all parts with ATF during assembly.

5. Install the conical spring washer, the reverse selector, the 35 x 47 x 7.8 mm collar, and all gears in the direction shown.

6. Replace the locknut and the conical spring washer with new ones when assembling the transmission. The countershaft locknut has left-hand threads.

7. Some reverse selector hubs and 3rd gears are press-fitted to the countershaft; special tools are needed to remove them (see page 14-290) and to install them (see page 14-290).

Mainshaft 5th Gear Axial Clearance

Inspection

Mainshaft 5th Gear Axial Clearance

Inspection

1. Remove the mainshaft transmission housing bearing

(seepage 14-270).

2. Install the thrust needle bearing ( A ) , 5th gear ( B ) , the

needle bearing (C), the thrust needle bearing (D), the

41 ...

Countershaft Reverse Selector Hub and

3rd Gear Removal

Countershaft Reverse Selector Hub and

3rd Gear Removal

1. Install a commercially available bearing separator on

4th gear (A). Set the countershaft (B) on a press with a

spacer (C) between the press and the countershaft,

and remove the reverse selector ...

See also:

Airbag and Tensioner Disposal

Special Tools Required

Deployment Tool 07HAZ-SG00500

Before scrapping any airbags, side airbags, side curtain

airbags, seat belt tensioners, (including those in a whole

vehicle to be scrapped), th ...

Protecting Small Children

Child Seat Type

Many states, Canadian provinces and

territories allow a child one year of

age or older who also meets the

minimum size and weight

requirements to transition from a

rear-fa ...

Component Location Index

2-door

4-door

...