Honda Accord: Countershaft Reverse Selector Hub and

3rd Gear Removal

Honda Accord: Countershaft Reverse Selector Hub and

3rd Gear Removal

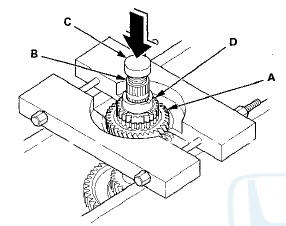

1. Install a commercially available bearing separator on 4th gear (A). Set the countershaft (B) on a press with a spacer (C) between the press and the countershaft, and remove the reverse selector hub (D).

NOTE: Some reverse selector hubs are not press-fitted, and can be removed without using the bearing separator and a press.

2. Remove the needle bearing, the set ring, the 35 x 47 x 7.8 mm collar, and the 31 mm cotters.

3. Set the countershaft (A) on the press with the spacer (B) between the press and the countershaft, and remove 3rd gear (C).

4. Remove the 37 x 41 x 54.3 mm collar, 5th gear, 1st gear, and 2nd gear.

Countershaft Disassembly, Inspection,

and Reassembly

Countershaft Disassembly, Inspection,

and Reassembly

1. Inspect the needle bearings for galling and rough movement.

2. Inspect the splines for excessive wear and damage.

3. Check the shaft bearing surface for scoring and excessive wear.

4. Lubr ...

Countershaft Reverse Selector Hub and

3rd Gear Installation

Countershaft Reverse Selector Hub and

3rd Gear Installation

Special Tools Required

Driver Handle, 40 mm I.D. 07746-0030100

1. Install 2nd gear, 1st gear, 5th gear, and the

37 x 41 x 54.3 mm collar on the countershaft.

2. Slide 3rd gear (A) over the count ...

See also:

Passenger's Under-dash Fuse/Relay

Box (MICU) Removal and

Installation

NOTE: SRS components are located in this area. Review

the SRS component locations 4-door (see page 24-21),

2-door (see page 24-23), and precautions, and

procedures (see page 24-25) before doing rep ...

If YouMust Drive with Several Children

Your vehicle has a back seat where

children can be properly restrained.

If you ever have to carry a group of

children, and a child must ride in

front:

Place the largest child in the front

se ...