Honda Accord: Secondary Shaft Bearing

Replacement

Honda Accord: Secondary Shaft Bearing

Replacement

Special Tools Required

•Driver Handle, 15 x 135L 07749-0010000

•Attachment, 62 x 68 mm 07746-0010500

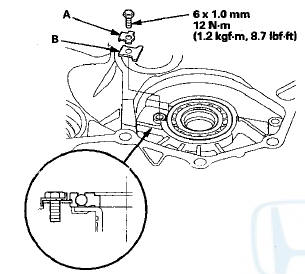

1. Remove the set plate bolt, then remove the lock washer (A) and the bearing set plate (B).

2. Remove the secondary shaft bearing (A) by heating the torque converter housing to about 212 В°F (100 В°C) using a heat gun (B). Do not heat the torque converter housing more than 212 В°F (100 В°C).

NOTE: Let the torque converter housing cool to normal temperature before installing the secondary shaft bearing.

3. Remove the ATF guide collar with the O-rings. Clean and dry the ATF guide collar surfaces and the torque converter housing if necessary.

4. Install new O-rings (A) on the ATF guide collar (B), then install the ATF guide collar in the torque converter housing.

5. Install a new secondary shaft bearing (C) in the direction shown.

6. Install the secondary shaft bearing using the driver handle and the 62 x 68 mm attachment, and install it securely in the torque converter housing.

7. Check that the bearing groove aligns with the torque converter housing surface, then install the bearing set plate with aligning the bearing groove.

8. Install a new lock washer and the set plate bolt, then bend the lock tab of the lock washer against the bolt head.

Countershaft Bearing Replacement

Countershaft Bearing Replacement

Special Tools Required

-Adjustable Bearing Puller, 2 5 - 4 0 mm 07736-A01000B

-Driver Handle, 15 x 135L 07749-0010000

-Attachment, 62 x 68 mm 07746-0010500

1. Remove the countershaft bearing using ...

Selector Control Shaft Oil Seal

Replacement

Selector Control Shaft Oil Seal

Replacement

Special Tools Required

-Driver Handle, 15 x 135L 07749-0010000

-Oil Seal Driver Attachment 07947-ZV00100

1. Remove the oil seal (A) from the torque converter

housing (B).

2. Install a new oil s ...

See also:

Features

The heating and air conditioning

system in your vehicle provides a

comfortable driving environment in

all weather conditions.

The standard audio system has

many features. This section

descr ...

VSA Modulator-Control Unit Removal and

Installation

N O T E :

- Do not spill brake fluid on the vehicle; it may damage

the paint. If brake fluid gets on the paint, wash it off

immediately with water.

- Be careful not to damage or deform the brake ...

Replacing the High-mount Brake Light Bulb

1. Open the trunk, and remove the

socket from the light assembly by

turning it one-quarter turn counterclockwise.

2. Pull the bulb straight out of its

socket. Push the new bulb straight

int ...