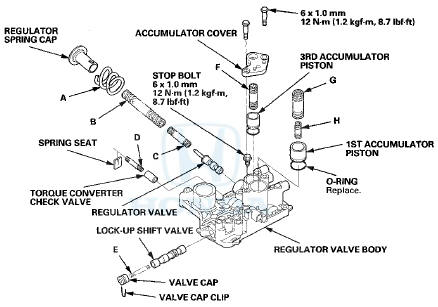

Honda Accord: Regulator Valve Body Disassembly,

Inspection, and Reassembly

Honda Accord: Regulator Valve Body Disassembly,

Inspection, and Reassembly

1. Clean all parts thoroughly in solvent and dry them with compressed air. Blow out all passages.

2. Inspect the valve body for scoring and damage.

3. Check all valves for free movement. If any fail to slide freely, do the valve body repair procedure (see page 14-275).

4. Hold the regulator spring cap in place while removing the stop bolt. The regulator spring cap is spring loaded.

5. Coat all parts with ATF during assembly.

6. Replace the O-rings with new ones.

7. When reassembling the valve body, align the hole in the regulator spring cap with the hole in the valve body, then press the spring cap into the valve body, and tighten the stop bolt.

SPRING SPECIFICATIONS

ATF Pump Inspection

ATF Pump Inspection

1. Install the ATF pump drive gear (A), the driven gear

(B), and the ATF pump driven gear shaft (C) in the

main valve body (D). Lubricate all parts with ATF, and

install the ATF pump driven gear wi ...

Servo Body Disassembly, Inspection,

and Reassembly

Servo Body Disassembly, Inspection,

and Reassembly

1. Clean all parts thoroughly in solvent, and dry them with compressed air.

Blow out all passages.

2. Inspect the valve body for scoring and damage.

3. Check shift valve D for free movement. I ...

See also:

Playing a USB Flash Drive

Your audio system reads and plays sound files on a USB flash drive in either

MP3,

WMA or AAC*1 format.

Connect your USB flash drive to the USB port, then press the AUX

button.

• How to Selec ...

Rear Inner Fender Replacement

NOTE: Take care not to scratch the rear bumper or the

body.

1. Remove the screws, then remove the rear inner

fender (A) from the rear bumper (B) and the body.

2. Install the inner fender in th ...

Front Seat-back Cover Replacement

Special Tools Required

- KTC Trim Tool Set SOJATP2014*

-Trim Pad Remover, Snap-on A177A or

equivalent,

commercially available

*Available through the Honda Tool and

Equipment

Program; call 888 ...