Honda Accord: Outboard Joint Side

Honda Accord: Outboard Joint Side

1. Wrap the splines on the driveshaft with vinyl tape (A) to prevent damaging the outboard boot.

2. Install new ear clamp bands (B) and the outboard boot onto the driveshaft, then remove the vinyl tape. Be careful not to damage the outboard boot.

3. Make sure to check the size of a new stop ring.

To avoid driveshaft and vehicle damage, make sure you install a new stop ring.

Stop ring specifications

4. Install the stop ring (A) into the driveshaft groove (B).

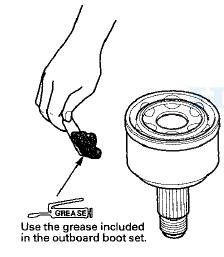

5. Pack about 35 g (1.2 oz) of grease included in the new outboard boot set into the driveshaft hole in the outboard joint.

NOTE* If you are installing a new outboard joint, the grease is already installed.

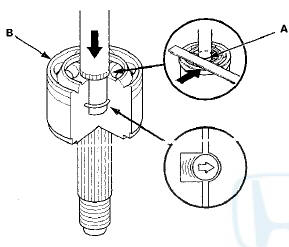

6. Insert the driveshaft (A) into the outboard joint (B) until the stop ring (C) is close to the joint.

7. To completely seat the outboard joint, pick up the driveshaft and the joint, and tap or hit the assembly onto a hard surface from a height of about 10 cm (4 in).

NOTE: Do not use a hammer, as excessive force may damage the driveshaft. Be careful not to damage the threaded section (A) of the outboard joint.

8. Check the alignment of the paint mark (A) you made with the outboard joint end (B).

To avoid driveshaft and vehicle damage, the shaft must be all the way into the outboard joint to ensure the stop ring is properly seated.

9. Pack the outboard joint (A) with the remaining joint grease included in the outboard boot set

Total grease quantity

Outboard pint:

10. Fit the boot ends (A) onto the driveshaft (B) and the outboard joint (C). Bleed any excess air from the boot by inserting a flat-tipped screwdriver between the boot and the joint.

11. Inspect the length (A) of the driveshafts to the figure as shown, then adjust the boots to halfway between full compression and full extension.

Left driveshaft

12. Close the ear portion (A) of the band using a commercially available seal clamp tool (Kent-Moore J-35910 or equivalent) (B).

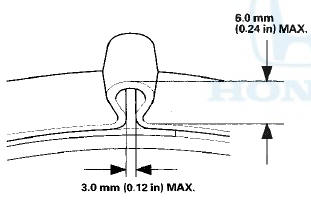

13. Check the clearance between the closed ear portion of the band. If the clearance is not within the standard, close the ear portion of the band tighter.

14. Repeat steps 12 and 13 for the band on the other end of the boot.

Inboard Joint Side

Inboard Joint Side

1. Wrap the splines with on the driveshaft vinyl tape (A)

to prevent damaging the inboard boot.

2. Install the inboard boot onto the driveshaft, then

remove the vinyl tape. Be careful not to dama ...

Driveshaft Installation

Driveshaft Installation

NOTE: Before starting Installation, make sure the mating

surfaces of the joint and the splined section are clean.

1 Apply about 5 g (0.18 oz) of moly 60 paste

(P/N 08734-0001) to the contact area ...

See also:

AM/FM Antenna Repair

NOTE: To make an effective repair, the broken section

must be no longer than one Inch.

1. Lightly rub the area around the broken section (A)

with fine steel wool, then clean it with isopropyl

al ...

Replacing a Front Turn Signal/Parking Light Bulb

1. Open the hood.

To change the turn signal bulb on

the passenger’s side, remove the

engine coolant reserve tank by

pulling it out of its stay.

Driver’s side on V6 models

Remove t ...