Honda Accord: Cam Chain Auto-tensioner Removal

and installation

Honda Accord: Cam Chain Auto-tensioner Removal

and installation

Removal

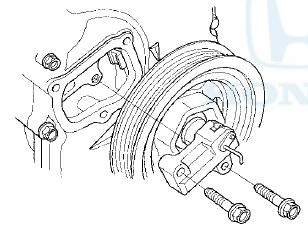

1.Remove the chain case cover

2. Turn the crankshaft counterclockwise to compress the auto-tensioner.

3. Align the holes on the lock (A) and the auto-tensioner (B), then insert a 1.2 mm (0.05 in) diameter pin or lock pin (P/N 14511-PNA-003) (C) into the holes. Turn the crankshaft clockwise to secure the pin.

4. Remove the auto-tensioner.

Installation

1. Install the auto-tensioner.

NOTE: Check the auto-tensioner cam position. If the position are not aligned, set the first cam to the first edge of the rack (see step 9 on page 6-66).

2. Remove the 1.2 mm (0.05 in) diameter pin or lock pin (P/N 14511-PNA- 003) from the auto-tensioner.

3. Remove the old liquid gasket from the chain case cover mating surfaces, the bolts, and the bolt holes.

4. Clean and dry the chain case cover mating surfaces.

5. Apply liquid gasket, P/N 08717-0004,08718-0003, or 08718-0009 to the chain case mating surface of the chain case cover, and to the inside edge of the threaded bolt holes. Install the component within 5 minutes of applying the liquid gasket.

NOTE: - Apply a 3 mm (0.12 in) diameter bead of liquid gasket along the broken line (A).

- If too much time has passed after applying the liquid gasket, remove the old liquid gasket and residue, then reapply new liquid gasket.

6. Install the chain case cover.

NOTE: - Wait at least 30 minutes before filling the engine with oil.

- Do not run the engine for at least 3 hours after installing the chain case cover.

Cam Chain Installation

Cam Chain Installation

Special Tools Required

Camshaft Lock Pin Set 07AAB-RWCA120

NOTE:

- Keep the cam chain away from magnetic fields.

- Before doing this procedure, check that the variable

valve timing control (VTC ...

Cam Chain Case Oil Seal

Installatio

Cam Chain Case Oil Seal

Installatio

Special Tools Required

Driver Handle, 15 x 135L 07749-0010000

Attachment, 52 x 55 mm 07746-0010400

1. Clean and dry the crankshaft oil seal.

2. Apply a light coat of new engine oil to the lip of ...

See also:

Clutch Fluid

Manual transmission only

The fluid level should be between

theMINandMAXmarks on the side

of the reservoir. If it is not, add

brake fluid to bring it up to that level.

Use the same fluid spec ...

Spotlights

Turn on a spotlight by pushing the

lens. Push the lens again to turn it

off. You can use the spotlights at all

times.

Except LX

The spotlights have a two-position

switch. In the DOOR pos ...

DTC Troubleshooting

DTC P0506: idle Control System RPM Lower

Than Expected

NOTE: Before you troubleshoot record all freeze data

and any on-board snapshot, and review the general

troubleshooting information (see page ...