Honda Accord: Secondary Shaft 2nd Gear Axial

Clearance Inspection

Honda Accord: Secondary Shaft 2nd Gear Axial

Clearance Inspection

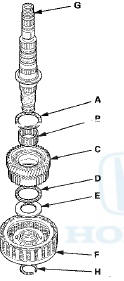

1. Install the thrust needle bearing (A), the needle bearing (B), 2nd gear (C), the thrust needle bearing (D), the 37 x 58 mm thrust washer (E), and the 2nd clutch (F) on the secondary shaft (G), then secure them with the set ring ( H ) . Do not install the O-rings during inspection.

2. Measure the clearance between the set ring (A) and the 2nd clutch guide (B) using a feeler gauge (C), in at least three places. Use the average as the actual clearance.

Standard: 0.04-0.12 mm (0.002-0.005 in)

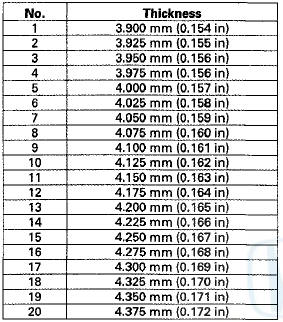

3. If the clearance is out of standard, remove the 37 x 58 mm thrust washer, and measure its thickness.

4. Select and install a new thrust washer, then recheck.

THRUST WASHER, 37 x 58 mm

5. After replacing the thrust washer, make sure the clearance is within standard.

6. Disassemble the installed parts from the secondary shaft.

Secondary Shaft Idler Gear Removal

and Installation

Secondary Shaft Idler Gear Removal

and Installation

Special Tools Required

Attachment 42 mm I.D. 07QAD-P0A0100

Removal

Place a spacer (A) on the secondary shaft (B), and set a

puller (C) under the idler gear (D), then remove the idler

gear.

Ins ...

Secondary Shaft 1 st Gear Axial

Clearance Inspection

Secondary Shaft 1 st Gear Axial

Clearance Inspection

Special Tools Required

Attachment, 42 mm I.D. 07QAD-P0A0100

1. Remove the secondary shaft transmission housing

bearing (see page 14-270).

2. Install the thrust needle b e a r i n g (A), the need ...

See also:

Outboard Joint Side

1. Wrap the splines on the driveshaft with vinyl tape (A)

to prevent damaging the outboard boot.

2. Install new ear clamp bands (B) and the outboard boot

onto the driveshaft, then remove the viny ...

Carrying Items in the Passenger Compartment

Store or secure all items that could

be thrown around and hurt

someone during a crash.

Do not put any items on top of the

rear shelf. They can block your

view and be thrown around the

vehic ...

How Your Side Curtain Airbags Work

In a moderate to severe side impact,

sensors will detect rapid acceleration

and signal the control unit to

instantly inflate the side curtain

airbag.

If the impact is on the passenger’s

...