Honda Accord: Countershaft Assembly Clearance Inspection

Honda Accord: Countershaft Assembly Clearance Inspection

tightened to the specified torque (see page 13-46).

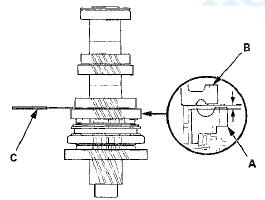

1. Measure the clearance between 1st gear (A) and the 1st gear distance collar (B) with a feeler gauge (C).

- If the clearance exceeds the service limit, go to step 2.

- If the clearance is within the service limit, go to step 4.

Standard: 0.06-0.16 mm (0.002-0.006 in)

Service Limit: 0.25 mm (0.010 in)

2. Measure the length of the 1st gear distance collar as shown.

- If the length is not within the standard, replace the 1st gear distance collar.

- If the length is within the standard, go to step 3.

Standard: 23.03-23.08 mm (0.907-0.909 in)

3. Measure the thickness of 1 st gear.

- If the thickness is less than the service limit, replace 1st gear. * - If the thickness is within the service limit, replace the 1st/2nd synchro hub and the reverse gear as a set.

Standard: 22.92~22.97 mm (0.902-0.904 In)

Service Limit: 22.87 mm (0.900 in)

4. Measure the clearance between 2nd gear (A) and 3rd gear (B) with a feeler gauge (C). If the clearance exceeds the service limit, go to step 5.

Standard: 0.06-0.16 mm f i . i i 2 - i . i i 6 in)

Service Limit: 0.25 mm (0.010 in)

5. Measure the length of the 2nd gear distance collar.

- If the length is not within the standard, replace the 2nd gear distance collar.

- If the length is within the standard, go to step 6.

Standard: 28.03-28.08 mm (1.104-1.106 in)

6. Measure the thickness of 2nd gear.

- If the thickness is less than the service limit, replace 2nd gear.

- If the thickness is within the service limit, replace the 1st/2nd synchro hub and reverse gear a s a set.

Standard: 27.92-27.97 mm (1.099-1.101 in)

Service Limit: 27.87 mm (1.097 in)

Mainshaft Reassembly

Mainshaft Reassembly

Exploded View

*: The components of the double cone synchro assembly.

Special Tools Required

- Driver Handle, 40 mm I.D. 07746-0030100

-СћBearing Driver Attachment, 30 mm

07746-0030300

NOTE: ...

Countershaft Disassembly

Countershaft Disassembly

NOTE: Refer to the Exploded View in the Countershaft

Reassembly, as needed, when removing components

pressed onto the countershaft (see page 13-46).

1. Securely clamp the countershaft assembly In ...

See also:

Timing Belt

V6 models

The timing belt should be replaced

according to the Maintenance

Minder TM.

Replace the timing belt every 60,000

miles (100,000 km) if you regularly

drive your vehicle in any of the ...

Gauge Control Module Replacement

NOTE: Before replacing the gauge control module, rewriting the ODO data and

transferring the maintenance minder

data to a new gauge control module (see page 22-350).

1. Remove the instrument vis ...

Warm Up TWC Removal/Installation

1. Raise the vehicle on a lift.

2. Remove the secondary H02S (Sensor 2) (see page

11-197).

3. Remove the bolts (A).

4. Remove the WU-TWC bracket (B).

5. Lower the vehicle.

6. Remove th ...