Honda Accord: Parking Brake Inspection and Adjustment

Honda Accord: Parking Brake Inspection and Adjustment

Inspection

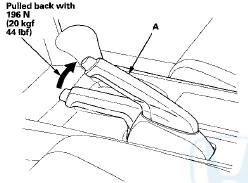

1. Pull the parking brake lever (A) with 196 N (20 kgf, 44 Ibf) of force to fully apply the parking brake.

The parking brake lever should be locked within the specified number of clicks.

Lever locked clicks: 7 to 9 clicks

2. If the number of lever clicks is not as specified, adjust the parking brake.

Adjustment

1. Release the parking brake lever fully.

2. Pull out the center console rear trim (A) (see page 20-160).

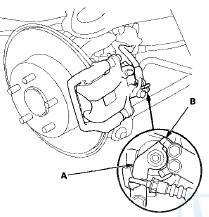

3. Loosen the parking brake adjusting nut (B).

4. Raise and support the vehicle (see page 1-13).

5. Remove the rear wheels.

6. Make sure the lever (A) on the rear brake caliper contacts the arm (B).

NOTE. The lever will contact the arm when the parking brake adjusting nut is loosened.

7. Clean the mating surfaces between the brake disc and the inside of the wheel, then install the rear wheels.

8. Pull the parking brake lever 1 click.

9. Tighten the parking brake adjusting nut until the parking brakes drag slightly when the rear wheels are turned.

10. Release the parking brake lever fully, and check that the parking brakes do not drag when the rear wheels are turned. Readjust if necessary.

11. Make sure the parking brake lever is within the specified number of clicks (7 to 9 clicks).

12. Install the center console rear trim (see page 20-160).

Brake Pedal and Brake Pedal Position Switch

Adjustment

Brake Pedal and Brake Pedal Position Switch

Adjustment

Pedal Height

1. Turn t h e brake p e d a l p o s i t i o n switch 45В°

counterclockwise, and pull it back until it is no longer

touching the brake pedal.

2. Remove the footrest (see step 4 on ...

Brake System Bleeding

Brake System Bleeding

NOTE:

- Do not reuse the drained fluid. Use only new Honda

DOT 3 Brake Fluid from an unopened container. Using

a non-Honda brake fluid can cause corrosion and

shorten the life of the system.

- ...

See also:

Differential Carrier and Final Driven

Gear Replacement

1. Remove the final driven gear (A) from the differential

carrier (B).

NOTE: Differential carrier bolts have left-hand

threads.

2. Install the final driven gear in the direction shown on

the ...

Switch Test/Replacement

1. Separate the lumbar support switch cover (A) from

the switch (B).

2. Disconnect the 5P connector (C) from the switch.

3. Check for continuity between the terminals in each

switch position a ...

Shift Lever Housing Replacement

NOTE:

- Use the appropriate tool from the KTC trim tool set to

avoid damage when removing components.

- Take care not to scratch the center console,

dashboard, and related parts.

1. Remove th ...