Honda Accord: Park Pin Switch Test

Honda Accord: Park Pin Switch Test

Produced in USA models

1. Remove the center console (see page 20-158).

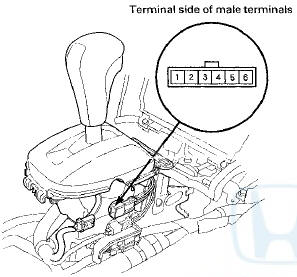

2. Disconnect the A/T gear position indicator panel light/park pin switch 6P connector (A) from the park pin switch (B).

3. Check for continuity between connector terminals No.

1 and No. 2.

There should be continuity.

• There should be continuity when the shift lever is moved out of P.

• There should be continuity when the shift lever is moved to P.

4. If continuity is not as specified, replace the park pin switch (see page 14-258).

Produced In Saitama models .

1. Remove the center console (see page 20-158).

2. Disconnect the A/T gear position indicator panel light/park pin switch 6P connector (A) from the park pin switch (B).

3. Check for continuity between connector terminals No.

1 and No. 2.

• There should be continuity when the shift lever is moved to P.

• There should be continuity when the shift lever is moved out of P.

4. In continuity is not as specified, replace the park pin switch (see page 14-258).

Key Interlock Solenoid Test

Key Interlock Solenoid Test

NOTE: SRS components are located in this area. Review

the SRS component locations for 4-door (see page

24-21),for 2-door (see page 24-23), and the precautions

and procedures (see page 24-25) before ...

Ignition Switch Test

Ignition Switch Test

NOTE: SRS components are located in the area. Review

the SRS component locations 4-door (see page 24-21),

2-door (see page 24-23), and precautions and

procedures (see page 24-25) before doing repai ...

See also:

Front Seat Belt Replacement

Front Seat Belt - 2-door

SRS components are located in this area. Review the

SRS component locations (see page 24-23) and the

precautions and procedures (see page 24-25) before

doing repairs or se ...

Audio-HVAC Subdisplay Unit

Removal/Installation

With Navigation

NOTE:

• Put on gloves to protect your hands.

• Take care not to scratch the dashboard.

1. Remove the dashboard center vent (see page 20-178).

2. Remove the screws, ...

ACC (Adaptive Cruise Control)*

Maintains a constant vehicle speed and a safe distance between your vehicle

and the

vehicle ahead of you without having to keep your foot on the brake pedal or

accelerator.

WARNING

Improper ...