Honda Accord: Front Brake Pad Inspection and Replacement

Honda Accord: Front Brake Pad Inspection and Replacement

Special Tools Required

Brake Caliper Piston Compressor 07AAE-SEPA101

Frequent inhalation of brake pad dust, regardless of material composition, could be hazardous to your health.

- Avoid breathing dust particles.

- Never use an air hose or brush to clean brake assemblies. Use an OSHA-approved vacuum cleaner.

Inspection - NISSIN Type

1. Raise and support the vehicle (see page 1-13).

2. Remove the front wheels.

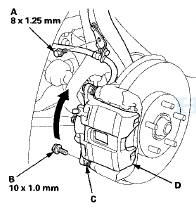

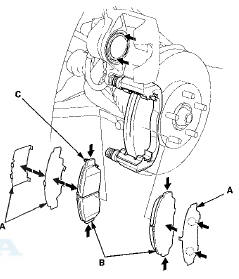

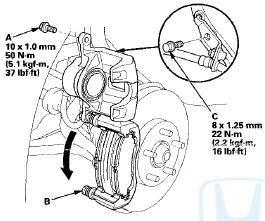

3. Remove the brake hose mounting bolt (A).

4. Remove the flange bolt (B) while holding the caliper pin (C) with a wrench. Be careful not to damage the pin boot, and pivot the caliper (D) up out of the way.

Check the hose and pin boots for damage and deterioration.

5. Check the thickness (A) of the inner pad (B) and the outer pad (C). Do not include the thickness of the backing plate.

Brake pad thickness:

Standard: 10.5 - 1 1 . 2 mm (0.41 - 0.44 in)

Service limit: 1.6 mm (0.06 in)

6. If any part of the brake pad thickness is less than the service limit, replace the front brake pads as a set.

7. Pivot the caliper down into position. Install the flange bolt (A), and tighten it to the specified torque while holding the caliper pin (B) with a wrench being careful not to damage the pin boot.

8. Install the brake hose mounting bolt (C).

9. Clean'the mating surfaces between the brake disc and the inside of the wheel, then install the front wheels.

Replacement - IMISSIN Type

1. Remove some brake fluid from the master cylinder.

2. Raise and support the vehicle (see page 1-13).

3. Remove the front wheels.

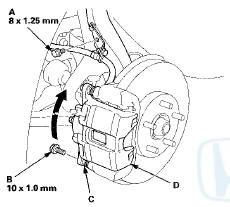

4. Remove the brake hose mounting bolt (A).

5. Remove the flange bolt (B) while holding the caliper pin (C) with a wrench. Be careful not to damage the pin boot, and pivot the caliper (D) up out of the way.

Check the hose and the pin boots for damage and

deterioration.

7. Remove the pad retainers (A).

8. Clean the caliper bracket (B) thoroughly; remove any rust, and check for grooves and cracks. Verify that the caliper pins (C) move in and out smoothly. Clean and lube if needed.

9. Inspect the brake disc for runout, thickness, parallelism (see page 19-19), and check for damage and cracks.

10. Apply a thin coat of M-77 assembly paste (P/N 08798-9010) to the retainer mating surface of the caliper bracket (indicated by the arrows).

11. Install the pad retainers. Wipe excess assembly paste off the retainers. Keep the assembly paste off the brake disc and the brake pads.

12. Install the brake caliper piston compressor tool (A) on the caliper body (B).

13. Press in the piston with the brake caliper piston compressor tool so the caliper will fit over the brake pads. Make sure the piston boot is in position to prevent damaging it when pivoting the caliper down.

NOTE: Be careful when pressing in the piston; brake fluid might overflow from the master cylinder's reservoir. If brake fluid gets on any painted surface, wash it off immediately with water.

14. Remove the brake caliper piston compressor tool.

15. Apply a thin coat of M-77 assembly paste (P/N 08798- 9010) to the pad side of the shims (A), the back of the brake pads (B) and the other areas indicated by the arrows. Wipe excess assembly paste off the pad shims and the brake pads friction material. Keep grease and assembly paste off the brake disc and the brake pads. Contaminated brake disc or brake pads reduce stopping ability.

16. Install the brake pads and the pad shims correctly.

Install the brake pad with the wear indicator (C) on the upper inside. If you are reusing the brake pads, always reinstall the brake pads in their original positions to prevent a temporary loss of braking efficiency.

17. Pivot the caliper down into position. Install the flange bolt (A), and tighten it to the specified torque while holding the caliper pin (B) with a wrench being careful not to damage the pin boot.

18. Install the brake hose mounting bolt (C).

19. Clean the mating surfaces between the brake disc and the inside of the wheel, then install the front wheels.

20. Press the brake pedal several times to make sure the brakes work.

NOTE: Engagement may require a greater pedal stroke immediately after the brake pads have been replaced as a set. Several applications of the brake pedal will restore the normal pedal stroke.

21. Add brake fluid as needed.

22. After installation, check for leaks at hose and line joints or connections, and retighten if necessary.

Test-drive the vehicle, then recheck for leaks (see page 19-39).

Inspection - AKEBONO Type

1. Raise and support the vehicle (see page 1 -13).

2. Remove the front wheels.

3. Check the thickness (A) of the inner pad (B) and the outer pad (C). Do not include the thickness of the backing plate.

Brake pad thickness:

Standard: 10.5-10.8 mm (0.41-0.43 in)

Service limit: 1.6 mm (0.06 in)

Inner pad

4. If any part of the brake pad thickness is less than the service limit, replace the front brake pads as a set.

5. Clean the mating surfaces between the brake disc and the inside of the wheel, then install the front wheels.

Replacement - AKEBONO Type

1. Remove some brake fluid from the master cylinder.

2. Raise and support the vehicle (see page 1-13).

3. Remove the front wheels.

4. Remove the brake hose mounting bolt (A).

5. Remove the flange bolt (B), and pivot the caliper (C) up out of the way. Check the hose and the pin boots for damage and deterioration.

6. Remove the pad shims (A) and the brake pads (B).

7. Remove the pad retainers (A).

8. Clean the caliper bracket (B) thoroughly; remove any rust, and check for grooves and cracks. Verify that the caliper pins (C) move in and out smoothly. Clean and lube if needed.

9. Inspect the brake disc for runout, thickness, parallelism (see page 19-19), and check for damage and cracks.

10. Apply a thin coat of M-77 assembly paste (P/N 08798-9010) to the retainer mating surface of the caliper bracket (indicated by the arrows).

11. Install the pad retainers. Wipe excess assembly paste off the retainers. Keep the assembly paste off the brake disc and the brake pads.

12. Install the brake caliper piston compressor tool (A) on the caliper body (B).

13. Press in the piston with the brake caliper piston compressor tool so the caliper will fit over the brake pads. Make sure the piston boot is in position to prevent damaging it when pivoting the caliper down.

NOTE: Be careful when pressing in the piston; brake fluid might overflow from the master cylinder's reservoir. If brake fluid gets on any painted surface, wash it off immediately with water.

14. Remove the brake caliper piston compressor tool.

15. Apply a thin coat of M-77 assembly paste (P/N 08798- 9010) to the pad side of the shims (A), the back of the brake pads (B) and the other areas indicated by the arrows. Wipe excess assembly paste off the pad shims and the brake pads friction material. Keep grease and assembly paste off the brake disc and the brake pads. Contaminated brake disc or brake pads reduce stopping ability.

16. Install the brake pads and the pad shims correctly.

Install the brake pad with the wear indicator (C) on the upper inside. If you are reusing the brake pads, always reinstall the brake pads in their original positions to prevent a temporary loss of braking efficiency.

17. Pivot the caliper down into position. Install the flange bolt (A), and tighten it to the specified torque.

18. Install the brake hose mounting bolt (B).

19. Clean the mating surfaces between the brake disc and the inside of the wheel, then install the front wheels.

20. Press the brake pedal several times to make sure the brakes work.

NOTE: Engagement may require a greater pedal stroke- immediately after the brake pads have been replaced as a set. Several applications of the brake pedal will restore the normal pedal stroke.

21. Add brake fluid as needed.

22. After installation, check for leaks at hose and line joints or connections, and retighten if necessary.

Test-drive the vehicle, then recheck for leaks (see page 19-39).

Brake Fluid Level Switch Test

Brake Fluid Level Switch Test

NOTE: If both the ABSA/SA indicator and the brake

system indicator come on at the same time, check the

VSA system for DTCs first (see page 19-48).

1. Disconnect the brake fluid level switch conne ...

Front Brake Disc Inspection

Front Brake Disc Inspection

Runout

1. Raise and support the vehicle (see page 1-13).

2. Remove the front wheels.

3. Remove the brake pads: NISSIN type (see page 19-14), AKEBONO type (see page

1947)

4. Inspect the bra ...

See also:

Change Lever Assembly Disassembly/Reassembly

NOTE: Prior to reassembling, clean all the parts in solvent, dry them, and

apply grease to contact surfaces as shown. Do

not wash the rubber parts with solvent.

...

Circuit Diagram

...