Honda Accord: Countershaft Inspection

Honda Accord: Countershaft Inspection

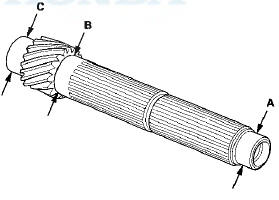

1. Inspect the gear and bearing contact areas for wear and damage, then measure the countershaft at points A, B, and C. If any part of the countershaft is less than the service limit, replace it.

Standard:

A Ball Bearing Contact Area

(Transmission Housing Side): 30.020-30.033 mm (1.1819-1.1824 in)

B 1st Gear Distance Collar Contact Area:

39.937-39.950 mm (1.5723-1.5728 in)

C Needle Bearing Contact Area

(Clutch Housing Side):

40.000-40.015 mm (1.5748-1.5754 in)

Service Limit:

A: 29.97 mm (1.180 in)

B: 39.88 mm (1.570 in)

C: 39.95 mm (1.573 in)

2. Inspect the runout by supporting both ends of the countershaft. Then rotate the countershaft two complete turns while measuring with a dial gauge. If the runout exceeds the service limit, replace the countershaft.

Standard: 0.02 mm (0.001 in) max.

Service Limit: 0.05 mm (0.002 in)

Countershaft Disassembly

Countershaft Disassembly

NOTE: Refer to the Exploded View in the Countershaft

Reassembly, as needed, when removing components

pressed onto the countershaft (see page 13-46).

1. Securely clamp the countershaft assembly In ...

Countershaft Reassembly

Countershaft Reassembly

Exploded View

*: The components of the triple cone synchro assembly.

Special Tools Required

-СћDriver Handle, 40 mm I.D. 07746-0030100

- Bearing Driver Attachment, 30 mm 07746-0030300

NOTE: R ...

See also:

Selector Centre! Sheft Bearing

Replacement

Special Tools Required

•Driver Handle, 15 x 135L 07749-0010000

-Attachment, 22 x 24 mm 07746-001A800

1. Remove the oil seal from the end cover, then remove

the bearing.

2. Install a new be ...

Installing a Child Seat with a Tether

A child seat with a tether can be

installed in any seating position in

the back seat, using one of the

anchorage points shown above.

Since a tether can provide additional

security to the la ...

Playing an iPod (Models without navigation system)

Playing an iPod (Models without navigation system) ...