Honda Accord: Transmission End Crankshaft Oil

Seal Installation - In Car.

Honda Accord: Transmission End Crankshaft Oil

Seal Installation - In Car.

Special Tools Required

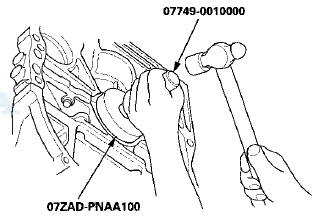

Driver Handle, 15 x 135L 07749-0010000

Oil Seal Driver Attachment, 96 mm 07ZAD-PNAA100

1 Remove the transmission: - Manual transmission (see page 13-7) - Automatic transmission (see page 14-194) 2. M/T model: Remove the flywheel (see step 17 on page 12-18), the clutch disc (see step 8 on page 12-16), and the pressure plate (see step 3 on page 12-15).

3. A/T model: Remove the drive plate (see page 14-204).

4. Clean and dry the crankshaft oil seal housing.

5. Apply a light coat of new engine oil to the lip of the crankshaft oil seal.

6. Use the driver handle, 15 x 135L and the oil seal driver attachment 96 mm to drive a new crankshaft oil seal squarely into the engine block to the specified installed height.

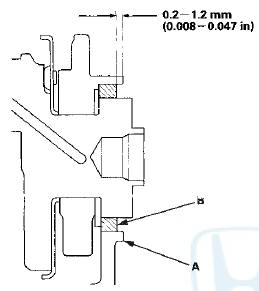

7. Measure the distance between the engine block (A)

and the crankshaft oil seal (B).

Oil Seal Installed Height: 0.2-1.2 mm

(0.008-0.047 In)

8. M/T model: Install the flywheel (see step 18 on page 12-18), the clutch disc (see step 26 on page 12-19), and the pressure plate (see step 27 on page 12-19).

9. A/T model: Install the drive plate (see page 14-204).

10. Install the transmission: - Manual transmission (see page 13-15) - Automatic transmission (see page 14-205)

Oil Pan Installation

Oil Pan Installation

1. Remove all of the old liquid gasket from the oil pan

mating surfaces, the bolts, and the bolt holes.

2. Clean and dry the oil pan mating surfaces.

3. Apply liquid gasket, P/N 08717-0004,0871 ...

Sealing Bolt Installation

Sealing Bolt Installation

NOTE: When installing the sealing bolt (A), always use a

new washer.

...

See also:

Sun Visor

To use the sun visor, pull it down.

When using the sun visor for the

side window, remove the support rod

from the clip, and swing it out.

In this position, the sun visor can be

adjusted by m ...

Adjusting the Sound

1. Press the SETTINGS button.

2. Rotate to select Audio

Settings, then

press .

3. Rotate to select Sound,

then press .

Rotate to scroll through the

following

choices:

The SVC ...

Evaporator Temperature Sensor Test

NOTE: Before testing the sensor, check for HVAC DTCs

(see page 2 1 - 9).

1. Remove the evaporator temperature sensor (see

page 21-67).

2. Dip the sensor in ice water, and measure the

resistan ...