Honda Accord: Shift Solenoid Valve Removal and

Installation

Honda Accord: Shift Solenoid Valve Removal and

Installation

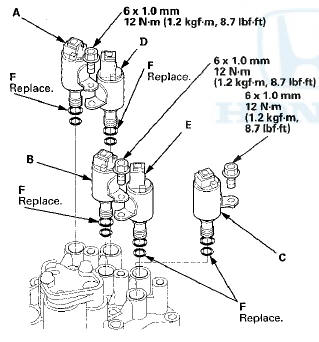

NOTE: -Do not hold the shift solenoid valve connector to remove and to install the shift solenoid valves. Hold the shift solenoid valve b o d y . -Do not install the shift solenoid valve A before installing the shift solenoid valve D, and do not Install shift solenoid valve B before shift solenoid valve E. If shift solenoid valves A and B are installed before shift solenoid valves D and E, it may damage the hydraulic control system.

1. Remove the shift solenoid valve mounting bolt, then remove the shift solenoid valves by holding the solenoid valve body. 2. Install new O-rings (two O-rings per shift solenoid valve) (F) on the shift solenoid valves.

NOTE: A new solenoid valve comes with new O-rings.

-If you install a new solenoid valve, use the O-rings provided with It.

3. Install shift solenoid valve D by holding the shift solenoid valve body; be sure that the mounting bracket contacts the servo body.

4. install shift solenoid valve A by holding the shift solenoid valve body; be sure that the mounting bracket contacts the bracket on shift solenoid valve D.

5. Install shift solenoid valve E by holding the shift solenoid valve body; be sure that the mounting bracket contacts the servo body.

6. Install shift solenoid valve B by holding the shift solenoid valve body; be sure that the mounting bracket contacts the bracket on shift solenoid valve E.

7. Install shift solenoid valve C by holding the shiftsolenoid valve body; be sure that the mounting bracket contacts the servo body.

8. Install the shift solenoid valve mounting bolts.

Servo Body Disassembly, Inspection,

and Reassembly

Servo Body Disassembly, Inspection,

and Reassembly

1. Clean all parts thoroughly in solvent, and dry them with compressed air.

Blow out all passages.

2. Inspect the valve body for scoring and damage.

3. Check shift valve D for free movement. I ...

See also:

Dashboard Center Lower Cover

Removal/Installation

Special Tools Required

KTC Trim Tool Set SOJATP2014*

*Available through the Honda Tool and

Equipment

Program; call 888-424-6857

SRS components are located in this area. Review the

SRS component ...

System Description

Security Alarm

The security alarm system is armed automatically after

the doors, hood, and trunk lid are closed and locked. For

the system to arm, the ignition switch must be in the

LOCK (0) posit ...

Oil Pump Chain inspection

1. Remove the oil pan (see page 7-11).

2. Measure the oil pump chain auto-tensioner rod

length. If the length is over the service limit, replace

the oil pump chain (see page 8-25).

Oil Pump Chai ...