Honda Accord: Rocker Arm Oil Control Valve

Removal/Installation

Honda Accord: Rocker Arm Oil Control Valve

Removal/Installation

All models except PZEV

1. Remove the strut brace (see page 20-306).

2. Disconnect the rocker arm oil control solenoid connector (A) and the rocker arm oil pressure switch connector (B).

3. Remove the harness clamps (C) and the bolts (D).

4. Remove the rocker arm oil control valve assembly (E) and the rocker arm oil control valve filter (F).

5. Remove the engine wire harness bracket (A) (also (B) (if equipped)) from the rocker arm oil control valve (C).

6. Install the parts in the reverse order of removal with a new rocker arm oil control valve filter.

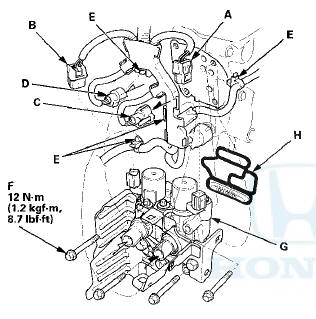

PZEV model

1. Remove the strut brace (see page 20-306).

2. Disconnect the rocker arm oil control solenoid A connector-(A), the rocker arm oil control solenoid B connector (B), the rocker arm oil pressure switch A connector (C), and the rocker arm oil pressure switch B connector (D).

3. Remove the harness clamps (E) and the bolts (F).

4. Remove the rocker arm oil control valve assembly (G) and the rocker arm oil control valve filter (H).

5. Remove the engine wire harness bracket (A) (also (B) (if equipped)) from the rocker arm oil control valve (C).

6. Install the parts in the reverse order of removal with a new rocker arm oil control valve filter.

CMP Sensor A Replacement

CMP Sensor A Replacement

1. Disconnect the CMP sensor A 3P connector (B).

2. Remove CMP sensor A from the intake camshaft side

of the cylinder head.

3. Install the parts in the reverse order of removal with a

new O-ri ...

Rocker Arm Oil Pressure Switch

Removal/Installation

Rocker Arm Oil Pressure Switch

Removal/Installation

All models except PZEV

1. Disconnect the rocker arm oil pressure switch

connector (A).

2. Remove the rocker arm oil pressure switch (B).

3. Install the parts in the reverse order of removal wi ...

See also:

Charging System Indicator

Circuit Troubleshooting

troubleshooting the charging system indicator.

1. Turn the ignition switch to ON (II).

Does the charging system indicator come on?

YES-Go to step 2.

NO-Go to step 14.

2. Start the engine. ...

Installing a Child Seat with a Tether

A child seat with a tether can be

installed in any seating position in

the back seat, using one of the

anchorage points shown above.

Since a tether can provide additional

security to the la ...

Symptom Troubleshooting

Rapid brake pad wear, vehicle vibration

(after a long drive), or high, hard brake pedal

NOTE: Make sure that the caliper pins are installed

correctly. Upper caliper pin B and lower caliper pin A ar ...