Honda Accord: Drive Belt Auto-tensioner

Inspection

Honda Accord: Drive Belt Auto-tensioner

Inspection

Special Tools Required

Belt Tension Release Tool Snap-on YA9317 or equivalent, commercially available

1. Turn the ignition switch to ON (II), and make sure to turn the A/C switch OFF. Turn the ignition switch to LOCK (0).

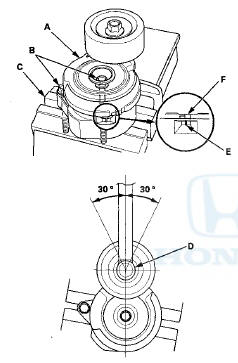

2. Check the position of the auto-tensioner indicator's pointer (A). Start the engine, then check the position again with the engine idling. If the position of the indicator moves or fluctuates very much, replace the auto-tensioner (see page 4-31).

3. Check for abnormal noise from the tensioner pulley. If you hear abnormal noise, replace the auto-tensioner pulley (see page 4-32).

4. Remove the drive belt (see page 4-30).

5. Move the auto-tensioner within its limit with the belt tension release tool in the direction of the rotation arrow. Check that the auto-tensioner moves smoothly and without any abnormal noise. If the auto-tensioner does not move smoothly, or if you hear abnormal noise, replace the auto-tensioner (see page 4-31).

6. Remove the auto-tensioner (see page 4-31).

7. Clamp the auto-tensioner (A) by using two 8 mm bolts (B) and a vise (C) as shown. Do not clamp the auto-tensioner itself.

8. Attach the torque wrench (D) on the pulley bolt, and align it as shown.

9. Align the auto-tensioner indicator's pointer (E) on the auto-tensioner base with Max. belt position mark (F) on the auto-tensioner arm by using the torque wrench, and measure the torque. If the torque value is out of specification, replace the auto-tensioner (see page 4-31).

NOTE: If the auto-tensioner indicator's pointer exceeds the Max. belt position mark, recheck the torque.

Auto-tensioner Spring Torque: 33.1 - 4 0 . 5 N-m (3.38-4.13 kgf-m, 24.4-29.9 Ibfft)

Drive Belt

Removal/Installation

Drive Belt

Removal/Installation

Special Tools Required

Belt Tension Release Tool Snap-on YA9317 or

equivalent, commercially available

1. Move the auto-tensioner (A) with the belt tension

release tool (B) in the direction of the ...

Drive Belt Auto-tensioner

Removal/Installation

Drive Belt Auto-tensioner

Removal/Installation

1. Remove the drive belt (see page 4-30).

2. Remove the power steering (P/S) fluid reservoir from

the holder.

3. Remove the P/S pump (A) without disconnecting the

P/S hoses, then remove the P/ ...

See also:

Carrier Bearing Replacement

Special Tools Required

Attachment, 40 x 50 mm 07LAD-PW50601

NOTE:

-The bearing and the bearing outer race should be

replaced as a set.

-Inspect and adjust the carrier bearing

preload

wheneve ...

Steering Lock Replacement

1. Remove the steering column (see page 17-10).

2. Center-punch both of the two shear bolts, and drill

their heads off with a 5 mm (0.20 in) drill bit. Be careful

not to damage the steering lock ...