Honda Accord: Oil Jet Replacement

Honda Accord: Oil Jet Replacement

1. Remove the oil pump (see page 8-17).

2. Remove the baffle plate (see step 8 on page 7-14).

3. Remove the oil jet bolts (A), then remove the oil jets (B).

4. Carefully install the oil jets, and tighten the oil jet bolts.

5. Install the baffle plate (see step 25 on page 7-29).

6. Install the oil pump (see page 8-23).

Oil Jet Inspection

1. Remove the oil jet (see page 8-14), and inspect it as follows.

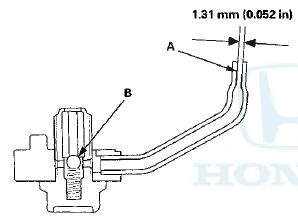

- Make sure that a 1.2 mm (0.05 in) diameter drill will go through the nozzle hole (A) (1.31 mm (0.052 in) diameter).

- Insert the other end of a 1.9 mm (0.07 in) drill into the oil intake (2.0 mm (0.079 in) diameter). Make sure the check ball (B) moves smoothly and has a stroke of about 2.0 mm (0.079 in).

- Check the oil jet operation with an air nozzle. It should take at least 325 kPa (3.9 kgf/cm2,47psi) to unseat the check ball.

NOTE: Replace the oil jet assembly, if the nozzle is damaged or bent.

2. Carefully install the oil jet. The mounting torque is critical.

Specified Torque: 16 N-m (1.6 kgf-m, 12 Ibfft)

Engine Oil Gallery Cap Replacement

Engine Oil Gallery Cap Replacement

1. Remove the harness bracket (A), then remove the

engine oil gallery cap (B).

2. Clean the O-ring groove and mating surface with the

engine oil gallery cap.

3. Apply new engine oil to new O-r ...

Oil Pump Overhaul

Oil Pump Overhaul

Exploded View

Oil Pump Removal

1. Turn the crankshaft pulley so its top dead center (TDC)

mark (A) lines up with the pointer (B).

NOTE: The other pointer (C) is not used.

2. Remove the oil ...

See also:

Middle Floor Undercover

Replacement

Left Side

NOTE:

- Put on gloves to protect your hands.

- Take care not to scratch the body.

1. Remove the bolts and release the hook (A), then

remove the left middle floor undercover (B).

...

Radiator and A/C Condenser Fan Low

Speed Circuit Troubleshooting

NOTE:

• Do not use this troubleshooting procedure

if the A/C

compressor is inoperative. Refer to the symptom

troubleshooting index.

• Before performing symptom troubleshooting, check ...

Circuit Diagram

...