Honda Accord: Precautions and Procedures

Honda Accord: Precautions and Procedures

General Precautions

NOTE: Some systems store data in memory that is lost when the battery is disconnected. Before disconnecting the battery, refer to Battery Terminal Disconnection and Reconnection (see page 22-91).

Please read the following precautions carefully before servicing the airbag system. Observe the instructions described in this manual, or the airbags could accidentally deploy and cause damage or injuries.

• Except when doing electrical inspections that requires battery power, always turn the ignition switch to LOCK (0), disconnect the negative cable from the battery, then wait at least 3 minutes before starting work.

NOTE: The SRS memory is not erased even if the ignition switch is turned to LOCK (0) or the battery cables are disconnected from the battery.

• Use replacement parts which are manufactured to the same standards and quality as the original parts. Do not install used SRS parts. Use only new parts when making SRS repairs.

• Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being dropped or improperly handled, such as dents, cracks or deformation.

• Before disconnecting the SRS unit connectors, always disconnect the appropriate SRS parts connectors.

• Use only a digital multimeter to check the system. If it is not a Honda multimeter, make sure its output is 10 mA (0.01 A) or less when switched to the lowest value in the ohmmeter range. A tester with a higher output could cause accidental deployment and possible injury.

• Do not put objects on the front passenger's airbag.

Steering-Related Precautions

Cable Reel Alignment

• Misalignment of the cable reel could cause an open in the wiring, making the SRS system, remote steering wheel controls, or the horn inoperative. Center the cable reel whenever you do the following (see step 6 on page 24-227).

- Installation of the steering wheel

- Installation of the cable reel

- Installation of the steering column

- Other steering-related adjustment or installation

• Do not disassemble the cable reel.

• Do not apply grease to the cable reel.

• If the cable reel shows any signs of damage, replace it with a new one. For example, if the cable reel does not rotate smoothly, replace it.

Airbag Handling and Storage

Do not disassemble an airbag. It has no serviceable parts. Once an airbag has been deployed, it cannot be repaired or reused.

For temporary storage of an airbag during service, observe the following precautions.

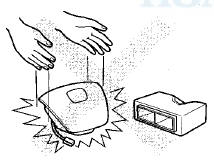

• Store the removed airbag with the pad surface up.

Never put anything on the airbag.

• To prevent damage to the airbag, keep it away from any oil, grease, detergent, or water.

Store the removed airbag on a secure, flat surface away from any high heat source (exceeding 200 В°F/ 93 В°C).

• Never do electrical tests on the airbags, such as measuring resistance.

• Do not position yourself in front of the airbag during removal, inspection, or replacement.

• For proper disposal of a damaged airbag, refer to airbag disposal (see page 24-222).

• The side curtain airbag module assembly is a long, jointed part containing an inflator (A), a flexible bag (B), and brackets (C). When removing or installing the side curtain airbag assembly, never: - Handle the flexible bag.

- Drop the airbag assembly.

- Cut, tear, or unwrap the tape strips.

4-Door

2-Door

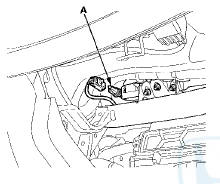

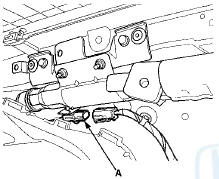

SRS' Unit, Front and Side impact Sensors, Rear Safing Sensor, Driver's Seat Position Sensor, and Front Passenger's Weight Sensors

NOTE: Some systems store data in memory that is lost when the battery is disconnected. Before disconnecting the battery, refer to Battery Terminal Disconnection and Reconnection (see page 22-91).

• Turn the ignition switch to LOCK (0), disconnect the negative cable from the battery, then wait at least 3 minutes before starting installation or replacement of the SRS unit or disconnecting the connectors from the SRS unit.

• Be careful not to bump or impact the SRS unit, the front impact sensors, the side impact sensors, or the rear safing sensor when the ignition switch is in ON (II), or for at least 3 minutes after the ignition switch is turned to LOCK (0).

• During installation or replacement, be careful not to bump (by impact wrench, hammer, etc.) the area around the SRS unit, the front impact sensors, the side impact sensors, or the rear safing sensor. The airbags could accidentally deploy and cause damage or injury.

• After a collision where the front airbags, the side airbags, the side curtain airbags, or the seat belt tensioners deploy, go to Component Replacement/Inspection after Deployment (see page 24-208). After a collision where the airbags or the side airbags do not deploy, inspect for any damage or any deformation on the SRS unit, the front impact sensors, the rear safing sensor, and the side impact sensors.

Also, do the front seat active head restraint inspection (see page 20-193). Replace all damaged parts.

• Do not disassemble the SRS unit, the front impact sensors, the side impact sensors, the rear safing sensor, the driver's seat position sensor, or the front passenger's weight sensors.

• Alway install the SRS unit, the driver's seat position sensor, all impact sensors, and the rear safing sensor securely with new TORX bolts torqued to 9.8 N-m (1.0 kgfm, 7.2 Ibf-ft).

• Do not spill water or oil on the SRS unit or any of the sensors.

Wiring Precautions

Some of the SRS wiring can be identified by a special yellow outer covering and the SRS connectors can be identified by their yellow color. Observe the following instructions, • Never attempt to modify, splice, or repair SRS wiring.

If there is an open or damage to the SRS wiring, replace the harness.

• Be sure to install the harness wires so they do not get pinched or interfere with other parts.

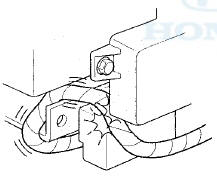

• Make sure all SRS ground locations are clean, and the grounds are securely fastened for optimum metal-to-metal contact. Poor grounds can cause intermittent problems that are difficult to diagnose.

• Do not use any silicone based cleaners or lubricants on any SRS connectors or terminals.

Precautions for Electrical Inspections

Special Tools Required

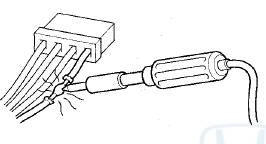

Back Probe Adapter, 17 mm 07TAZ-001020A

• Make sure the battery is fully charged when doing electrical test. Ifthe battery is not fully charged, the results of the tests may not be accurate.

• When using electrical test equipment, insert the probe of the tester into the wire side of the connector {except water proof connector). Do not insert the probe of the tester into the terminal side of the connector, and do not tamper with the connector.

• Use the back probe adaptor, 17 mm (07TAZ-001020A).

Do not insert the probe forcibly.

• Use specified service connectors in troubleshooting.

Using improper tools could cause a diagnostic error due to poor metal-to-metal contact.

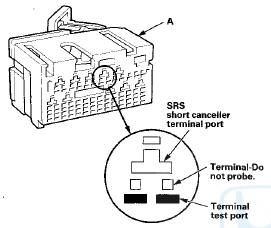

SRS Unit Connectors

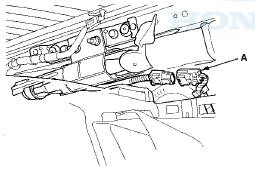

When diagnosing or troubleshooting at an SRS unit connector (A), use the terminal test port below the terminal you need to check. Gently insert the pin probes of the tester or jumper wire at the terminal test port from the terminal side.

Terminal side of female terminals

NOTE: • Do not insert the pin probes of the tester or a jumper wire at the terminal port or the SRS short canceller terminal port.

• To prevent damage to the connector terminals, do not insert the test equipment probes, paper clips, or other substitutes as they can damage the terminals.

Damaged terminals cause a poor connection and an incorrect measurement.

Water Proof SRS Connectors

When diagnosis/troubleshooting is done at water proof connector (A), use the terminal test port above the terminal you need to check. Gently contact the pin probe of the tester or jumper wire at the terminal test port from the terminal side.

Terminal side of female terminals

NOTE: • Do not insert the pin probes of the tester or a jumper wire into the terminal port.

• To prevent damage to the connector terminals, do not insert the test equipment probes, paper clips, or other substitutes as they can damage the terminals.

Damaged terminals can cause a poor connection and an incorrect measurement.

Lever-Looked Connector

The SRS unit connectors have a lever lock.

SRS Unit Connectors

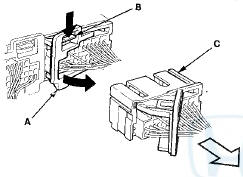

Disconnecting

To release the lock, pull the lever (A) while pushing the lock (B) on the outside of the connector, then pull out the connector (C).

Connecting

To reconnect the connector, push in on the connector (A). As the connector is pressed in, the lever (B) moves to the locked position.

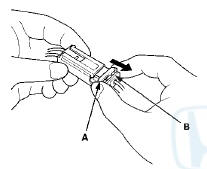

Spring-loaded Lock Connector

Some SRS connectors have a spring-loaded lock.

Front Airbag Connectors

Disconnecting

To release the lock, pull the spring-loaded sleeve (A) toward the stop (B) while holding the opposite half of the connector, then pull the connector halves apart. Be sure to pull on the sleeve and not on the connector.

Connecting

To reconnect, hold the pawl-side connector, and press on the back of the sleeve-side connector in the direction shown. As the two connector halves are pressed together, the sleeve (A) is pushed back by the pawl (B).

Do not touch the sleeve.

Side Airbag Connector

Disconnecting

To release the lock, pull the spring-loaded sleeve (A) toward the stop (B) while holding the opposite half of the connector, then pull the connector halves apart. Be sure to pull on the sleeve and not on the connector half.

Connecting

Hold both connector halves, and press them firmly together until the projection (A) of the sleeve-side connector clicks.

Opening the SRS Unit Shorting Connectors for Diagnosis

Special Tools Required

SRS Short Canceller 070AZ-SAA0100

NOTE: • To prevent damage to the connector cavity, insert an SRS short canceller straight into the cavity from the terminal side.

• Before installing an SRS short canceller, wash it with electrical contact cleaner, then dry it with compressed air.

• Do not use an SRS short canceller if it is damaged.

• Make sure to remove an SRS short canceller before reconnecting the SRS unit connector.

• Some systems store data in memory that is lost when the battery is disconnected. Before disconnecting the battery, refer to Battery Terminal Disconnection and Reconnection (see page 22-91).

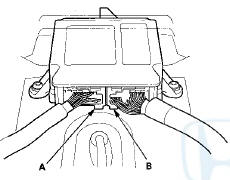

When SRS unit connector A (39P) or B (39P) is disconnected, a short circuit is automatically created in the connector to prevent accidental deployment of an airbag or tensioner. The circuit may need to be opened sometimes when diagnosing the system. Insert an SRS short canceller (070AZ- SAA0100) in the specified cavities when necessary to keep the circuit open for diagnosis.

Terminal numbers are shown from the wire side of the female terminals. Insert the SRS short canceller(s) into the cavities on the terminal side of the connector.

SRS UNIT CONNECTOR A (39P)

Insert short canceller(s) here.

Wire side of female terminals

SRS UNIT CONNECTOR B (39P)

Insert short canceller(s) here.

Wire side of female terminals

Seats with Side Airbags

Seats with side airbags have a "SIDE AIRBAG" label on the seat-back.

• Clean the seats with a damp cloth. Do not soak the seats with liquid. Do not spray steam on the seats.

• Do not repair a torn or frayed seat-back cover/pad.

Replace the seat-back cover/pad if it is damaged.

• After a collision where the side airbag was deployed, replace the side airbag and the seat frame with new parts. Ifthe seat-back cushion is split, it must be replaced. Refer to Component Replacement/Inspection After Deployment {see page 24-208).

• Never put aftermarket accessories on the seats (covers, pads, seat heaters, lights, etc.).

Disconnecting System Connectors

1. Turn the ignition switch to LOCK (0). Do the battery terminal disconnection procedure (see page 22-91), then wait at least 3 minutes before starting work.

Driver's Airbag

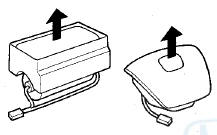

2. Remove the access panel (A) from the steering wheel, then disconnect the driver's airbag 4P connector (B) from the cable reel 4P connector.

Front Passenger's Airbag

3. Open the glove box. Remove the glove box stop on the right side, then let the glove box hang down (see page 20-174).

4. Detach the connector clip, then disconnect the dashboard wire harness 4P connector (A) from front passenger's airbag 4P connector.

Side Airbag

5. Disconnect the SRS floor wire harness 2P connectors (A) from the driver's and the front passenger's side airbag 2P connectors.

Side Curtain Airbag

6. Remove the C-pillar trim: • 4-door { s e e page 20-123).

• 2-door ( s e e page 20-119).

7. Disconnect both SRS floor wire harness 2P connectors (A) from the side curtain airbag 2P connectors.

4-Door

2-Door

Seat Belt Tensioner

8.4-door: Remove the B-pillar lower trim (see page 20-110).

9.2-door: Remove the rear side trim panel (see page 20-127).

10. Disconnect both SRS floor wire harness 4P connectors (A) from the seat belt tensioner 4P connectors.

SRS Unit

11. Remove the driver's and passenger's dashboard center lower cover (see page 20-170).

12. Remove the audio disc changer (with navigation system) (see page 23-118) or center pocket (without navigation system) (see page 20-168).

13. Disconnect SRS unit connectors A (39P) and B (39P) from the SRS unit.

Component Location Index

Component Location Index

4-Door

4-Door

2-Door

2-Door

...

General Troubleshooting Information

General Troubleshooting Information

DTC (Diagnostic Trouble Codes)

The self-diagnostic function of the SRS unit allows it to

locate the causes of system problems and store this

information in memory. For easier troubleshooting, this

...

See also:

Trunk Lid Opener Cable/Fuel Fill Door

Opener Cable Replacement

SRS components are located in this area. Review the

SRS component locations, 2-door (see page 24-23),

4-door (see page 24-21) and the precautions and

procedures (see page 24-25) before doing repair ...

Reverse Lockout

6-speed manual transmission only

The manual transmission has a

lockout so you cannot accidentally

shift from any forward gear to

reverse while the vehicle is moving

at a certain speed. If you ...

Before Driving

Before you begin driving your

vehicle, you should know what

gasoline to use and how to check the

levels of important fluids. You also

need to know how to properly store

luggage or packages. ...