Honda Accord: Control Arm Replacement

Honda Accord: Control Arm Replacement

1. Raise and support the vehicle {see page 1-13).

2. Remove the rear wheel.

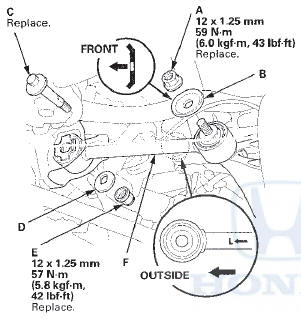

3. Remove the control arm mounting self-locking nut (A) and the washer (B) from the knuckle side.

NOTE; Use a new self-locking nut during reassembly.

4. Mark the cam positions of the adjusting bolt (C) and the adjusting cam plate (D) with the frame.

5. Remove the self-locking nut (E) while holding the adjusting bolt then remove the adjusting cam plate, the adjusting bolt, and the control arm (F).

NOTE: Use a new adjusting bolt and a new self-locking nut during reassembly.

6. Install the control arm in the reverse order of removal, and note these items: - First install all of the components, and lightly tighten the bolts and the nuts, then raise the suspension to load it with the vehicle's weight before fully tightening to the specified torque.

- Position the extended surfaces of the cam on the adjusting bolt and the adjusting cam plate facing down.

- Align the cam positions of the adjusting bolt and the adjusting cam plate with the marked positions on the frame when tightening the self-locking nut.

- Before installing the wheel, clean the mating surfaces on the brake disc and the inside of the wheel.

7. Check the wheel alignment, and adjust it if necessary (see page 18-5).

Lower Arm A Replacement

Lower Arm A Replacement

1. Raise and support the vehicle (see page 1-13).

2. Remove the rear wheel.

3. Remove the parking brake cable mounting bolt (B).

4. Remove the lower arm A mounting bolts, then

remove lower a ...

Lower Arm B Replacement

Lower Arm B Replacement

1 Raise and support the vehicle (see page 1-13).

2. Remove the rear wheel.

3. Remove the lower arm B mounting bolts, then

remove lower arm B.

NOTE: Use new mounting bolts during reassembly.

...

See also:

Symptom Troubleshooting

Hard Steering

NOTE:

-Compare to a known-good vehicle that is the same

trim level.

-Check for suspension damage.

m Check the steering alignment.

-Check the tire condition and pressure.

1 ...

Component Location Index

2-door

4-door

...

Vehicle Identification Number

Manufacturer, Make, and Type of Vehicle

1HG: Honda of America Mfg., Inc.

Honda passenger vehicle

JHM: Honda Motor Co., Ltd.

Honda passenger vehicle

Line, Body, and Engine Type

CP2: Accord/ ...