Honda Accord: Alternator and Regulator

Circuit Troubleshooting

Honda Accord: Alternator and Regulator

Circuit Troubleshooting

Special Tools Required

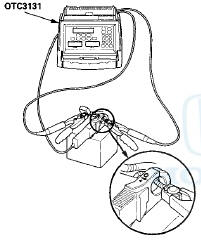

Alternator, Regulator, Battery, and Starter Tester OTC3131* ^Available through the Honda Tool and Equipment Program 888-424-6857

1. Make sure the battery connections are good and the battery is sufficiently charged.

2. Connect the alternator, regulator, battery & starter tester (OTC3131) to the battery as shown.

NOTE: The probe is used for alternator testing.

3. Start the engine. Hold the engine speed at 3,000 rpm with no load (in N or P (A/T model) or neutral (M/T model)) until the radiator fan comes on, then let it idle.

4. Do the CHARGING SYSTEM TEST.

Does the display indicate voltage within 13.5-”15.1 V and amperage of 87.5 A or more? YES-Go to step 5.

NO-lf the voltage is less than 13.5 V, go to alternator control circuit troubleshooting (see page 4-28). If the voltage is over 15.1 V and amperage is less than 87.5 A, replace the alternator (see page 4-32) or repair the alternator (see page 4-34).

5. Check the diode condition on the display.

Does the display indicate GOOD? YES-The diode is OK. Troubleshooting is complete.ll NO-lf the display indicates BAD, replace the alternator (see page 4-32) or repair the alternator (see page 4-34), then retest.B NOTE If the display indicates N/A, the diode pattern could not be diagnosed. Repeat the test. If N/A appears repeatedly, replace the alternator.

Charging System Indicator

Circuit Troubleshooting

Charging System Indicator

Circuit Troubleshooting

troubleshooting the charging system indicator.

1. Turn the ignition switch to ON (II).

Does the charging system indicator come on?

YES-Go to step 2.

NO-Go to step 14.

2. Start the engine. ...

Alternator Control Circuit

Troubleshooting

Alternator Control Circuit

Troubleshooting

NOTE: Do this troubleshooting if, in step 5 of the

alternator and regulator circuit troubleshooting (see

page 4-27), the battery voltage is less than 13.5 V.

* 1. Connect the Honda Diagnostic Sys ...

See also:

Brake System Indicator Circuit Diagram

...

Component Location Index

2-door

4-door

...

To Choose a Track

You can also choose a track directly

from a track list. Press ENTER on

the interface selector, and the track

list screen will be shown. If there are

no track names, track numbers are

displ ...