Honda Accord:

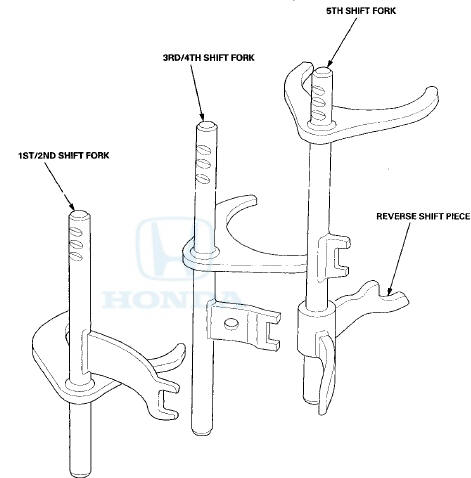

Shift Fork Disassembly/Reassembly

Honda Accord:

Shift Fork Disassembly/Reassembly

Eighth generation (2008–2012) / Honda Accord MK8 2008-2012 Service Manual / Transaxle / Manual Transmission /

Shift Fork Disassembly/Reassembly

NOTE: Prior to reassembling, clean all the parts in solvent, dry them, and apply MTF to all contact surfaces

Shift Fork Clearance Inspection

Shift Fork Clearance Inspection

1. Measure the clearance between each shift fork (A)

and its matching synchro sleeve (B). If the clearance

exceeds the service limit, go to step 2.

Standard: 0.35-0.65 mm (0.014-0.026 inj

Service ...

Mainshaft Assembly Clearance Inspection

Mainshaft Assembly Clearance Inspection

1. Support the bearing Inner race with an appropriate

sized socket ( A ) , and push down on the mainshaft ( B ) .

2. Measure the clearance between 2nd gear (C) and 3rd

gear (D) with a feeler gaug ...

See also:

To Stop Playing Your iPod

To play the radio, press the FM/AM,

or button. Press the CD button

to switch to the disc mode. Press the

AUX button to switch back to the

iPod.

Disconnecting an iPod

You can disconnect the ...

Menu Display

To select any setting such as the

clock, sound adjusting, or the

compass (if equipped), press the

MENU button. To use any audio

system function, the ignition switch

must be in the ACCESSORY ...

Circuit Diagram

...