Honda Accord: Mainshaft Assembly Clearance Inspection

Honda Accord: Mainshaft Assembly Clearance Inspection

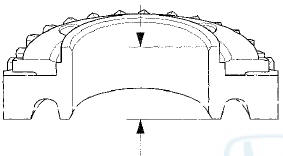

1. Support the bearing Inner race with an appropriate sized socket ( A ) , and push down on the mainshaft ( B ) .

2. Measure the clearance between 2nd gear (C) and 3rd gear (D) with a feeler gauge (E).

- If the clearance exceeds the service limit, go to step 3.

- If the clearance is within the service limit, go to step 4.

Standard: 0.06-0.16 mm (0.002-0.006 in)

Service Limit: 0.25 mm (0.010 in)

3. Measure the thickness of 3rd gear.

- If the thickness is less than the service limit, replace 3rd gear.

- If the thickness is within the service limit, replace the 3rd/4th synchro hub and the 3rd/4th synchro sleeve as a set.

Standard: 23.92-23.97 mm (0.942-0.944 in)

Service Limit: 23.80 mm (0.937 in)

4. Measure the clearance between 4th gear ( A ) and the 4th/5th gear distance collar ( B ) with a dial indicator (C).

- If the clearance exceeds the service limit, go to step 5.

e If the clearance is within the service limit, go to step 7.

Standard: 0.06-”0.16 mm (0.002-0.006 in)

Service Limit: 0.25 mm (0.010 in)

5. Measure the length of the

of the

4th/5th gear distance

collar as shown.

- If the length  is not within the

is not within the

standard, replace

the 4th/5th gear distance collar,

- If the length

is within the standard, go to step 6.

Standard: 24.03-24.08 mm (0.946-0.948 in)

6. Measure the thickness of 4th gear, - If the thickness is less than the service limit, replace 4th gear.

- Sf the thickness is within the service limit, replace the 3rd/4th synchro hub and the 3rd/4th synchro sleeve as a set.

Standard: 23.92-23.97 mm (0.942-0.944 in)

Service Limit: 23.80 mm (0.937 in)

7. Measure the clearance between the 4th/5th gear distance collar (A) and 5th gear (B) with a dial indicator (C).

- If the clearance exceeds the service limit, go to step 8.

- If the clearance is within the service limit, go to step 10.

Standard: 0.06-0.16 mm (0.002-0.006 in)

Service Limit: 0.25 mm (0.010 in)

8. Measure the length  of the

of the

4th/5th gear distance

collar as shown.

- If the length  is not within the

is not within the

standard, replace

the 4th/5th gear distance collar.

- If the length is within the

is within the

standard, go to step 9.

Standard: 24.03-24.08 mm (0.946-0.948 in)

9. Measure the thickness of 5th gear.

- If the thickness is less than the service limit, replace 5th gear.

- If the thickness is within the service limit, replace the 5th synchro hub and 5th synchro sleeve as a set.

Standard: 23.92-23.97 mm (0.942-0.944 in)

Service Limit: 23.80 mm (0.937 in)

10. Measure the length of the MBS distance collar. If the length is not within standard, replace the MBS distance collar.

Standard: 23.95-24.05 mm (0.943-0.947 in)

Shift Fork Disassembly/Reassembly

Shift Fork Disassembly/Reassembly

NOTE: Prior to reassembling, clean all the parts in solvent, dry them, and

apply MTF to all contact surfaces

...

Mainshaft Disassembly

Mainshaft Disassembly

NOTE: Refer to the Exploded View in the Mainshaft

Reassembly, as needed, when removing components

pressed onto the mainshaft (see page 13-38).

1. Remove the angular ball bearing (A) and the taper ...

See also:

Side Impact Sensor (First) Replacement

4-Door

Removal

1. Do t h e battery t e r m i n a l d i s c o n n e c t i o n procedure (see

page 22-91), t h e n w a i t at least 3 m i n u t e s before

s t a r t i ng work.

2. Remove t h e B-p ...

Voice Control Switch

Replacement

1. Remove the steering wheel (see page 17-6).

2. Remove the voice control switch (see page 17-7).

3. Install the voice control switch in the reverse order of

removal. ...

Front Bumper Fog Light Cover

Replacement

2-door

NOTE; Take care not to scratch the front bumper.

1. Remove the front bumper (see page 20-255).

2. Remove the screws (A, B), then remove the front

bumper fog light cover (C) from the fro ...