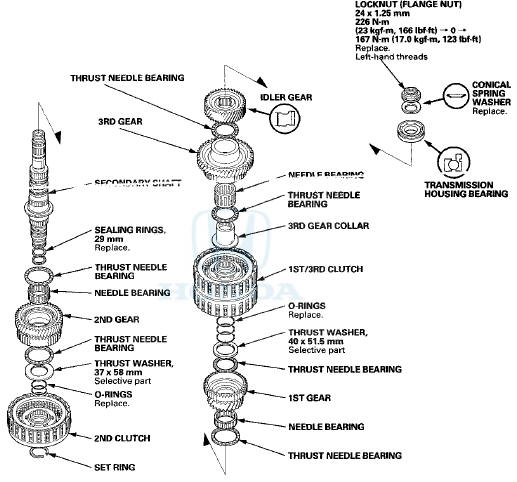

Honda Accord: Secondary Shaft Disassembly,

Inspection, and Reassembly

Honda Accord: Secondary Shaft Disassembly,

Inspection, and Reassembly

1. Inspect the thrust needle bearings a n d the needle bearings for g a l l i n g and rough movement

2. Inspect the splines for excessive wear and damage.

3. Check the shaft bearing surface for scoring and excessive wear.

4. Before installing new O-rings, wrap the shaft splines with tape to prevent O-ring damage.

5. Lubricate all parts with ATF during assembly.

6. Install the conical spring washer, and the idler gear in the direction shown.

7. Replace the locknut and the conical spring washer with new ones when assembling the transmission. The locknut has left-hand threads.

8. Check the clearance of 2nd gear (see page 14-294) and 1st gear (see page 14-295).

Countershaft Reverse Selector Hub and

3rd Gear Installation

Countershaft Reverse Selector Hub and

3rd Gear Installation

Special Tools Required

Driver Handle, 40 mm I.D. 07746-0030100

1. Install 2nd gear, 1st gear, 5th gear, and the

37 x 41 x 54.3 mm collar on the countershaft.

2. Slide 3rd gear (A) over the count ...

Secondary Shaft Idler Gear Removal

and Installation

Secondary Shaft Idler Gear Removal

and Installation

Special Tools Required

Attachment 42 mm I.D. 07QAD-P0A0100

Removal

Place a spacer (A) on the secondary shaft (B), and set a

puller (C) under the idler gear (D), then remove the idler

gear.

Ins ...

See also:

Ground Distribution

Ground to Components Index

* 1 : EX-L, EX-L PZEV

*2: Except EX-L, EX-L PZEV

*3: With premium audio system

*4: With navigation system

*5: '10 model

*6: '08-09 models ...

Daytime Running Lights

The high beam headlights come on slightly dimmer than normal when the

following

conditions have been met:

The parking/daytime running lights come on when the following conditions have

been ...

ECM/PCM Update

Special Tools Required

- Honda diagnostic system (HDS) tablet tester

- Honda Interface Module (HIM) and an iN workstation

with the latest HDS software version

- HDS pocket tester ...