Honda Accord: Brake Booster Replacement

Honda Accord: Brake Booster Replacement

1. Remove the cowl cover (see page 20-278).

2. Remove the strut brace (if equipped) (see page 20-306).

3. Remove the master cylinder (see page 19-26).

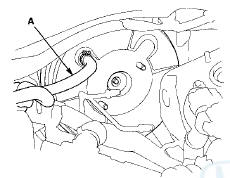

4. Disconnect the brake booster vacuum hose (A) from the brake booster.

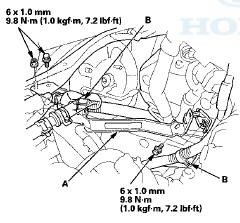

5. Remove the under-hood fuse/relay box bracket (A), then remove the engine wire harness clamps (B).

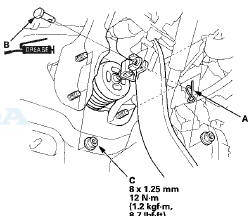

6. Remove the brake lines (A) from the hose clamp (B).

7 Remove the lock pin (A) and the clevis pin (B), then disconnect the yoke from the brake pedal.

8. Remove the brake booster mounting nuts (C).

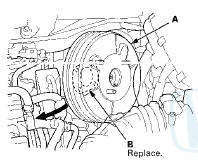

9. Remove the brake booster (A) from the engine compartment.

- Be careful not to damage the brake booster mounting surfaces and the threads on the booster studs.

- Be careful not to bend or damage the brake lines.

NOTE: Use the new brake booster gasket (B) during reassembly.

10. Install the brake booster in the r e v e r s e order of removal, and note these items: - Install the master cylinder after installing the brake booster (see page 19-26).

- Check the brake pedal height and free play after installing the master cylinder, and adjust it if necessary (see page 19-6).

- Bleed the brake system (see page 19-9).

Brake Booster Test

Brake Booster Test

Functional Test

1. With the ignition switch in LOCK (0), press the brake

pedal several times to deplete the vacuum reservoir,

then press the brake pedal hard and hold it for

15 seconds. If the bra ...

Rear Brake Pad Inspection and Replacement

Rear Brake Pad Inspection and Replacement

CAUTION

Frequent inhalation of brake pad dust, regardless of

material composition, could be hazardous to your

health.

- Avoid breathing dust particles.

-Never use an air hose or brush to clea ...

See also:

Interior Rearview Mirror

Adjust the angle of the rearview mirror when you are sitting in the correct

driving

position.

• Rearview Mirror with Day and Night Positions*

Flip the tab to switch the position.

The nigh ...

Park Pin Switch Replacement

Type A Shift Lever

NOTE: The AfT gear position indicator panel light

harness and the park pin switch are not available

separately. Replace the A/T gear position indicator panel

light harness and t ...

Ground Distribution

Ground to Components Index

* 1 : EX-L, EX-L PZEV

*2: Except EX-L, EX-L PZEV

*3: With premium audio system

*4: With navigation system

*5: '10 model

*6: '08-09 models ...