Honda Accord: Driveshaft Disassembly

Honda Accord: Driveshaft Disassembly

Special'Tools Required

•Threaded Adapter, 26 x 1.5 mm 07XAC-001030A

-Slide Hammer 5/8M-18 UNF, commercially available

-Bearing Puller, commercially available

-Boot Band Pliers, commercially available

Inboard Joint Side

1. Remove the boot bands. Be careful not to damage the boot.

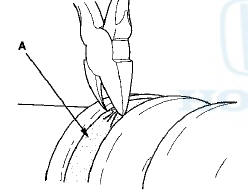

-If the boot band is a welded type (A), cut the boot band.

-If the boot band is a double loop type (B), lift up the band end (C), and push It into the clip (D).

-If the boot band is a low profile type (E), pinch the boot band using commercially available boot band pliers (F).

Welded type

Low profile type

2. Make marks (A) on each roller (B) and the inboard joint (C) to identify the locations of the rollers to the grooves in the inboard joint.

NOTE: Do not engrave or scribe any marks on the rolling surface.

3. Remove the inboard joint on a clean shop towel (D).

Be careful not to drop the rollers when separating them from the inboard joint.

4 . Make marks (A) on the spider (B) that match the marks on the rollers, then remove the rollers.

NOTE: Do not engrave or scribe any marks on the rolling surface.

5. Remove the circlip (C).

6. Make marks (D) on the spider and the driveshaft (E) to identify the position of the spider on the shaft.

7. Remove the spider.

NOTE: If necessary, use a commercially available puller while being careful not to damage the spider.

8. Wrap the splines on the driveshaft with vinyl tape (A) to prevent damaging the inboard boot.

9. Remove the inboard boot. Be careful not to damage the boot.

10. Remove the vinyl tape.

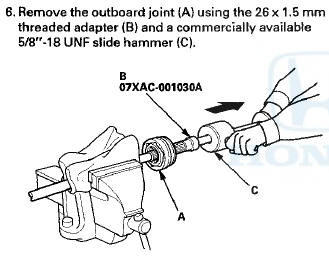

Outboard Joint Side

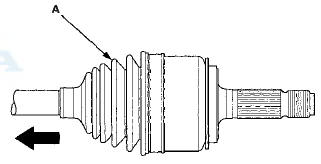

1 Remove the boot bands (A). Lift up the three tabs (B) using a screwdriver, then release the band. Be careful not to damage the boot.

2. Slide the outboard boot (A) partially toward the inboard joint side. Be careful not to damage the boot.

3. Wipe off the grease to expose the driveshaft and the outboard joint inner race.

4. Make a mark (A) on the driveshaft (B) at the same level

as the outboard joint end (C).

5. Securely clamp the driveshaft in a bench vise with a

shop towel wrapped around the driveshaft.

7. Remove the driveshaft from the bench vise.

8. Remove the stop ring from the driveshaft.

9. Wrap the splines on the driveshaft with vinyl tape (A)

to prevent damaging the outboard boot,

Driveshaft Removal

Driveshaft Removal

Special Tools Required

-Ball Joint Thread Protector, 14 mm 07AAE-SJAA100

-Ball Joint Remover, 28 mm 07MAC-SL0A202

1. Raise and support the vehicle, (see page 1-13)

2. Remove the front wheels.

3 ...

Dynamic Damper Replacement

Dynamic Damper Replacement

1. Remove the Inboard joint (see page 16-7).

2. Remove the dynamic damper band (see step 1 on

page 16-7).

3. Remove the dynamic damper (A).

Left driveshaft

Right driveshaft

4. Install a ...

See also:

Carrying Cargo

Your vehicle has several convenient

storage areas:

Glove box

Door and seat-back pockets

Roof-rack (if installed)

Center pockets

Console compartment

Trunk, including the rear seat

when fold ...

Secondary H02S Replacement

Special Tools Required

02 Sensor Wrench Snap-on S6176 or equivalent,

commercially available

1. Disconnect the secondary H02S 4P connector (A),

then remove the secondary H02S (B).

2. Install the ...

Selecting a Child Seat

When buying a child seat, you need

to choose either a conventional child

seat, or one designed for use with

the Lower Anchors and Tethers for

CHildren (LATCH) system.

Conventional child seats ...