Honda Accord: A/C Line Replacement

Honda Accord: A/C Line Replacement

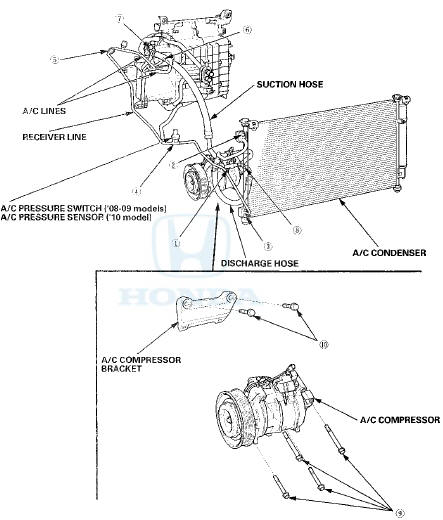

1.Discharge hose to the A /C compressor (6 x 1.0 mm): S.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

2.Discharge hose to the A /C condenser (6x1.Р’В© mm): 9.8 N-m f 1.0 kgf-m, 7.2 Ibf-ft)

3.Receiver line to the A /C condenser (6 x 1.0 mm): 9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

4.A/C pressure switch or A /C pressure sensor to the receiver line (11 x 1.0 mm): 10.8 N-m (1.1 kgf-m, 8.0 Ibf-ft)

5.Receiver line to the A /C line (16 x 1.5 mm): 13.7 N-m (1.4 kgfm, 10.1 ibf-ft)

6.A/C lines to the evaporator (6x 1.0 mm): 9.8 N-m (1.0 kgfm, 7.2 Ibf-ft)

7.A/C line to the suction hose (6x 1.0 mm): 9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

8.Suction hose to the A /C compressor (6 x 1.0 mm): 9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

9.A/C compressor to the A /C compressor bracket (8 x 1.25 mm): 22 N-m (2.2 kgfm, 16 Ibf-ft)

10.A/C compressor bracket to the engine block (1Р’В© x 1.25 mm): 44 N-m (4.5 kgfm, 32.5 Ibf-ft)

A/C Refrigerant Oil Replacement

A/C Refrigerant Oil Replacement

Recommended PAG oil: DENSO ND-OIL 8

P/N 38897-PR7-A01AH: 120 m l (4 fl-oz)

It is important to have the correct amount of refrigerant

oil in the A/C system to ensure proper lubrication of the

A/C c ...

A/C System Inspection

A/C System Inspection

Before troubleshooting any problem with the air

conditioning system, do the following:

1. With the ignition switch in LOCK (0), inspect the A/C

components, the pressure lines and the hoses for

sta ...

See also:

Using the Paddle Shifters in the D position (D-Paddle Shift Mode)

V6 models only

When you are driving in theD

position, you can shift the

transmission up or down manually

with the paddle shifters.

To shift up or down, use the +

(right) or - (left) paddl ...

Front Seat Removal/Installation

Special Tools Required

KTC Trim Tool Set SOJATP2014*

*Available through the Honda Tool and

Equipment

Program; call 888-424-6857

SRS components are located in this area. Review the

SRS component ...

Shift Lever Installation

1. Install the shift lever assembly (A).

Type A Shift Lever

Type B Shift Lever

2. Connect the shift lock solenoid connector (B) and the

park pin switch/A/T gear position indicator panel light

...