Honda Accord: Valve, Spring, and Valve Seal Installation

Honda Accord: Valve, Spring, and Valve Seal Installation

Special Tools Required

Stem Seal Driver, 30 mm 07PAD-0010000

Valve Spring Compressor Attachment 07757-PJ1010A

1. Coat the valve stems with new engine oil. Install the valves in the valve guides.

2. Check that the valves move up and down smoothly.

3. Install the spring seats on the cylinder head.

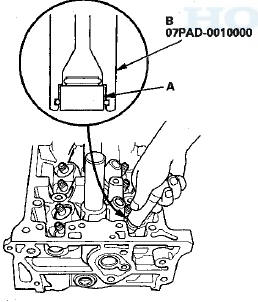

4. Install the new valve seals (A) using the 5.5 mm side of the stem seal driver, 30 mm (B).

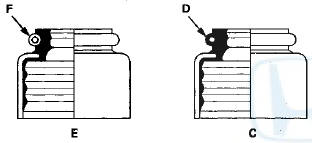

NOTE: The exhaust valve seal (C) has a black spring (D), and the intake valve seal (E) has a white spring (F).

They are not interchangeable.

5. Install the valve spring and the spring retainer. Place the end of the valve spring with the closely wound coils toward the cylinder head.

6. Install the valve spring compressor attachment and the valve spring compressor. Compress the spring, and install the valve cotters.

7. Remove the valve spring compressor and the valve spring compressor attachment.

8. Lightly tap the end of each valve stem two or three times with a plastic mallet (A) to ensure proper seating of the valve and the valve cotters. Tap the valve stem only along its axis so you do not bend the stem.

Valve Seat Reconditioning

Valve Seat Reconditioning

1. Inspect the valve stem-to-guide clearance (see page

6-88). If the valve guides are worn, replace them (see

page 6-88) before cutting the valve seats.

2. Renew the valve seats in the cylinder h ...

Rocker Arm Assemblf Installation

Rocker Arm Assemblf Installation

1. Reassemble the rocker arm assembly (see page 6-82).

2. Clean and dry the No. 5 rocker shaft holder mating

surface.

3. Apply liquid gasket P/N 08717-0004, 08718-0003, or

08718-0009 to the cy ...

See also:

Carrying Items in the Passenger Compartment

Store or secure all items that could

be thrown around and hurt

someone during a crash.

Do not put any items on top of the

rear shelf. They can block your

view and be thrown around the

vehic ...

Adjusting the Sound

BASS, TREBLE, FADER, and

BALANCE are each adjustable. You

can also adjust the strength of the

sound coming from the subwoofer

speaker. In addition, you can set the

speed-sensitive volume

c ...

Starter Performance Test

1. Remove the starter (see page 4-11).

2. Firmly clamp the starter in a vise.

3. Make a connection for this test using the thickest

(gauge) wire possible (preferably the same gauge as

used on ...