Honda Accord: Mainshaft 5th Gear Axial Clearance

Inspection

Honda Accord: Mainshaft 5th Gear Axial Clearance

Inspection

1. Remove the mainshaft transmission housing bearing (seepage 14-270).

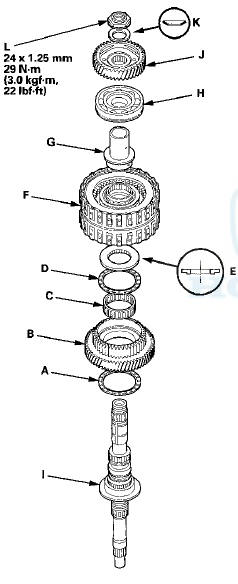

2. Install the thrust needle bearing ( A ) , 5th gear ( B ) , the needle bearing (C), the thrust needle bearing (D), the 41 x 68 mm thrust washer (E), the 4th/5th clutch (F), the 4th gear collar (G), and the transmission housing bearing ( H ) on the mainshaft ( I ) . Do not install the O-rings during inspection.

3. Install the idler gear (J) on the mainshaft with a press, then install the conical spring washer (K) and the locknut (L).

4. Tighten the locknut to 29 N-m (3.0 kgfm, 22 Ibf-ft).

5. Set a dial indicator ( A ) on 5th gear ( B ) .

6. Lift 5th gear (A) up while holding the mainshaft, and use the dial indicator (B) to read the 5th gear axial clearance.

7. Measure the 5th gear axial clearance in at least three places while moving 5th gear. Use the average as the actual clearance.

Standard: 0.04-0.10 mm (0.002-0.004 In)

8. If the clearance is out of standard, remove the 41 x 68 mm thrust washer and measure its thickness (A).

3. Select and install a new thrust washer, then recheck.

THRUST WASHER, 41 x 68 mm

10. After replacing the thrust washer, make sure the clearance is within the standard.

11. Disassemble the installed parts from the mainshaft.

12. Reinstall the transmission housing bearing in the transmission housing (see page 14-271).

Mainshaft Disassembly, Inspection,

and Reassembly

Mainshaft Disassembly, Inspection,

and Reassembly

1. Inspect the thrust needle bearings and the needle bearings for galling and

rough movement

2. Inspect the splines for excessive wear and damage.

3. Check the shaft bearing surface for scorin ...

Countershaft Disassembly, Inspection,

and Reassembly

Countershaft Disassembly, Inspection,

and Reassembly

1. Inspect the needle bearings for galling and rough movement.

2. Inspect the splines for excessive wear and damage.

3. Check the shaft bearing surface for scoring and excessive wear.

4. Lubr ...

See also:

Check Fuel Cap Message

If your fuel fill cap is loose or

missing, a ‘‘CHECK FUEL CAP’’

message appears on the information

display after you start the engine. ...

Changing the Engine Oil and Oil Filter

You must change the engine oil and oil filter regularly in order to maintain

the

engine's lubrication. The engine may be damaged if they are not changed

regularly.

Change the oil and filter in ...

All ChildrenMust Be Restrained

Each year, many children are injured

or killed in vehicle crashes because

they are either unrestrained or not

properly restrained. In fact, traffic

collisions are the number one cause

of dea ...