Honda Accord: Countershaft Bearing Replacement

Honda Accord: Countershaft Bearing Replacement

Special Tools Required

- Oil Seal Driver, 65 07JAD-PL90100

- Adjustable Bearing Puller, 20-”40 mm 07736-A01000B

- Slide Hammer 3/8"-16 UNF, commercially available

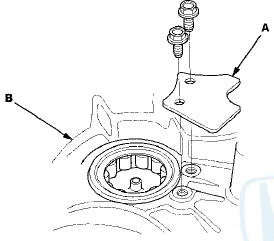

1. Remove the bearing set plate (A) from the clutch housing (B).

2. Remove the needle bearing (A)

2. Remove the needle bearing (A)

using the 20-”40 mm

adjustable bearing puller (B) and a commercially

available 3/8"-16 UNF slide hammer (D), then remove

oil guide plate C.

3. Position oil guide plate C and a new needle bearing (A) in the bore of the clutch housing (B).

4. Install the needle bearing using the 65 oil seal driver (D).

5. Install the bearing set plate (A) with bolts (B).

Mainshaft Bearing and Oil Seal Replacement

Mainshaft Bearing and Oil Seal Replacement

Special Tools Required

- Oil Seal Driver, 65 07JAD-PL90100

- Adjustable Bearing Puller, 20-”40 mm 07736-A01000B

- Bearing Driver Attachment, 42 x 47 07746-0010300

- Driver Handle, 15 x 135L ...

Mainshaft Thrust Clearance Adjustment

Mainshaft Thrust Clearance Adjustment

Special Tools Required

- Mainshaft Holder 07GAJ-PG20110

- Mainshaft Base 07GAJ-PG20130

1. Remove the 72 mm shim (A) and oil guide plate M

from the transmission housing (B).

2. Thoroughly clea ...

See also:

Front Grille Replacement

Special Tools Required

KTC Trim Tool Set SOJATP2014*

* Available through the Honda Tool and

Equipment

Program; call 888-424-6857

Grille Replacement - 2-door

NOTE:

- Take care not to scratch th ...

Secondary Shaft 2nd Gear Axial

Clearance Inspection

1. Install the thrust needle bearing (A), the needle

bearing (B), 2nd gear (C), the thrust needle bearing

(D), the 37 x 58 mm thrust washer (E), and the 2nd

clutch (F) on the secondary shaft (G), t ...

Pump Pressure Test w i th T/N 07406-0010001

Special Tools Required

-Pump Joint Adapter 07RAK-S040111 or P/S Joint

Adapter (pump) 07RAK-S040110

-Hose Joint Adapter 07RAK-S040122

-P/S Pressure Gauge 07406-0010001

Check the fluid pressure as ...