Honda Accord: 4th and 5th Clutch Reassembly

Honda Accord: 4th and 5th Clutch Reassembly

Special Tools Required

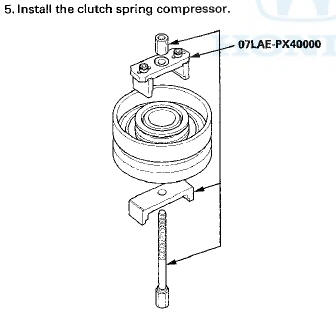

Clutch Spring Compressor Set 07LAE PX40000 1. Soak the clutch discs thoroughly in ATF for at least 30 minutes.

2. Install new O-rings (A) on the clutch piston (B). Do not twist the O-rings.

3. Install the clutch piston (A) in the clutch drum (B) while applying pressure and rotating to ensure proper seating. Do not pinch the O-ring.

4. Set the return spring (A) and the spring retainer (B) on the clutch piston, and position the snap ring (C) on the spring retainer.

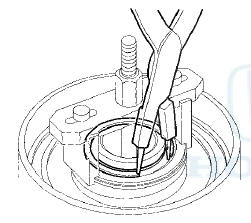

6. Be sure the clutch spring compressor (A) is adjusted to make f u l l contact with the spring retainer (B).

7. Check the placement of the clutch spring compressor, If either end of the clutch spring compressor is set over an area of the spring retainer that is unsupported by the return spring, the retainer may be damaged.

8. Compress the return spring until the snap ring can be installed.

9. Install the snap ring using snap ring pliers.

10. Remove the clutch spring compressor.

11. Install the wave spring (A) in the 4th clutch drum (B).

Starting with the clutch wave-plate, alternately install the wave-plates (C) (4) and the clutch discs (D) (4).

Install the clutch end-plate (E) with the flat side toward the top disc.

12. Install the wave spring (A) in the 5th clutch drum (B).

Starting with the clutch wave-plate, alternately install the wave-plates (C) (4) and the clutch discs (D) (4).

Install the clutch end-plate (E) with the flat side toward the top disc.

13. Install the snap ring using a screwdriver to secure the clutch end-plate.

14. Check that the clutch piston moves by applying air pressure into fluid passage.

1st, 2nd, and 3rd Clutch Reassembly

1st, 2nd, and 3rd Clutch Reassembly

Special Tools Required

Clutch Spring Compressor Set 07LAE-PX40000

NOTE: Hold the spring compressor in a vise with soft

jaws. Be careful not to damage the clutch drum.

1 Soak the clutch discs tho ...

Valve Body

Valve Body

Valve Body and ATF Strainer

Installation

Exploded View

Torque Specifications:

6 x 1.0 mm: 12 N-m (1.2 kgf m, 8.7 Ibfft)

8 x 1.25 mm: 18 N-m (1.8 kgfm, 13 Ibfft)

NOTE: Refer to the Exploded Vie ...

See also:

XM Radio Display Messages

‘‘LOADING’’ - XM is loading the audio or program information.

‘‘OFF AIR’’ - The channel currently selected is no longer

broadcasting.

‘‘UPDATING’’ - The encryption code is ...

How the Passenger Airbag Off Indicator Works

This indicator alerts you that the

passenger’s front airbag has been

shut off because weight sensors

detect about 65 lbs (29 kg) or less

(the weight of an infant or small

child) on the f ...