Honda Accord: Wheel Bolt Replacement

Honda Accord: Wheel Bolt Replacement

Special Tools Required

B a i l Joint Remover, 28 mm 07MAC-SL0A202

- Do not use a hammer or impact tools (pneumatic or electric) to remove and install the wheel bolts.

- Be careful not to damage the threads of the wheel bolts.

Front

1. Remove the front hub (see page 18-14).

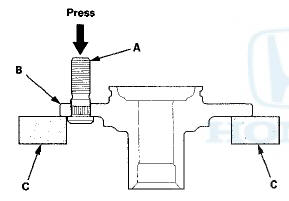

2. Separate the wheel bolt (A) from the hub (B) using a hydraulic press. Support the hub with hydraulic press attachments (C) or equivalent tools.

NOTE: Before installing the new wheel bolt, clean the mating surfaces on the bolt and the hub.

3. Insert the new wheel bolt into the hub while aligning the splined surfaces on the hub hole with the wheel bolt.

NOTE: - Degrease the area around the wheel bolt.

- Make sure the wheel bolt is installed vertically in relation to the hub disc surface.

4. Install the wheel bolt using a hydraulic press until the wheel bolt shoulder is fully seated.

5. Install the front hub (see page 18-14).

NOTE: If you cannot tighten the wheel nut to the specified torque when installing the wheel, replace the front hub as an assembly.

Rear

1. Raise and support the vehicle (see page 1-13).

2. Remove the rear brake disc (see page 19-34).

3. Separate the wheel bolt (A) from the hub (B) using the ball joint remover (C), and keep the jaw (D) of ball joint remover vertical against the wheel bolt (see page 18-10).

NOTE: - If the angle of the remover against the wheel bolt is not square, readjust the ball joint remover by turning the head (E) of the adjusting bolt (F).

- Before installing the new wheel bolt, clean the mating surfaces on the bolt and the hub.

4. Insert the new wheel bolt (A) into the hub (B) while aligning the splined surfaces (C) on the hub hole with the wheel bolt. Adjust the measurement (D) with the washers (P/N 94101-12800 or equivalent) (E), then install a nut (P/N 90304-SC2-000 or equivalent) (F) hand-tight.

NOTE: - Degrease the area around the wheel bolt and the threaded section of the nut.

- Make sure the wheel bolt is installed vertically in relation to the hub disc surface.

- Do not install the nut and the washers that have been used as tools on a vehicle.

5. Tighten the nut until the wheel bolt is drawn fully into the hub. Do not exceed the maximum torque limit.

Make sure there is no gap (G) between the bolt and the hub.

Limited torque:

108 N-m (11.0 kgf-m, 80 Ibf-ft) max.

6. Install the rear brake disc (see page 19-34).

NOTE: - If you cannot tighten the wheel nut to the specified torque when installing the wheel, replace the rear hub bearing unit as an assembly.

- Before installing the wheel, clean the mating surfaces of the brake disc and the inside of the wheel.

Wheel Runout Inspection

Wheel Runout Inspection

1. Raise and support the vehicle (see page 1 -13).

2. Check for a bent or deformed wheel.

3. Set up the dial gauge as shown, and measure the

axial runout by turning the wheel.

Front and rear w ...

Ball Joint Removal

Ball Joint Removal

Special Tools Required

- Ball Joint Thread Protector, 14 mm 07AAE-SJAA100

- Ball Joint Thread Protector, 12 mm 07AAF-SDAA100

- Ball Joint Thread Protector, 10 mm 07AAF-SECA120

- Ball Joint Remover ...

See also:

Stabilizer Bar Replacement

1. Raise and support the vehicle (see page 1-13).

2. Remove the rear wheels.

3. Disconnect both stabilizer links from the stabilizer bar

(see page 18-47).

4. Remove the flange bolts (A) and ...

Rear Window Replacement

NOTE:

- Put on gloves to protect your hands.

- Wear eye protection while cutting the glass adhesive

with a piano wire.

- Use seat covers to avoid damaging any surfaces.

- Do not damage the ...

Under-floorTWC Removal/Installation

1. Raise the vehicle on a lift.

2. Remove the exhaust pipe hangers (A).

3. Remove the under-floor TWC (B).

4. Install the parts in the reverse order of removal with

new gaskets (C) and new s ...