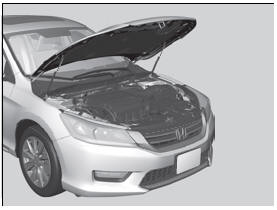

Honda Accord: Opening the Hood

Honda Accord: Opening the Hood

1. Park the vehicle on a level surface, and set

the parking brake.

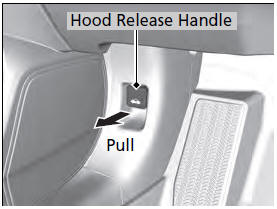

2. Pull the hood release handle under the

lower left corner of the dashboard.

- The hood will pop up slightly.

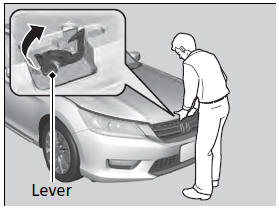

3. Push up the hood latch lever in the center of the hood to release the lock mechanism, and open the hood.

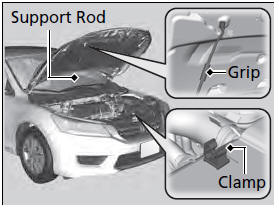

4. Remove the support rod from the clamp using the grip. Mount the support rod in the hood.

When closing, remove the support rod, and stow it in the clamp, then gently lower the hood. Remove your hand at a height of approximately 12 inches (30 cm) and let the hood close.

4. Lift the hood up most of the way.

- The hydraulic supports will lift it up the

rest of the way and hold it up.

When closing, lower it to approximately 12 inches (30 cm), then press down firmly with your hands.

NOTICE

Do not open the hood when the wiper arms are raised.

The hood will strike the wipers, and may damage either the hood or the wipers.

When closing the hood, check that the hood is securely latched.

If the hood latch lever moves stiffly, or if you can open the hood without lifting the lever, the latch mechanism should be cleaned and lubricated.

Recommended Engine Oil

Recommended Engine Oil

Oil is a major contributor to your engine's

performance and longevity. If you drive the

vehicle with insufficient or deteriorated oil,

the engine may fail or be damaged.

This seal indicates ...

See also:

Identification Numbers

Your vehicle has several identifying

numbers in various places.

The vehicle identification number

(VIN) is the 17-digit number your

dealer uses to register your vehicle

for warranty purpose ...

PIN Number

You can add, change, or remove a

PIN number from any phonebook.

To add a PIN:

If you have selected a phonebook

without a PIN, you will see the above

display.

Enter the new 4-digit PIN. You ...

To Use Maintenance MinderTM

• Displaying the Engine Oil Life

1. Turn the ignition switch to ON

.

2. Press the (Select/Reset) knob

repeatedly

until the engine oil life appears on the

information display.

The Maint ...