Honda Accord: Driver's Power Seat Motor Test

Honda Accord: Driver's Power Seat Motor Test

1. Remove the d r i v e r ' s seat (see page 20-194).

2. Remove t h e p o w e r seat adjustment switch knobs a nd t h e recline cover f r om t h e seat.

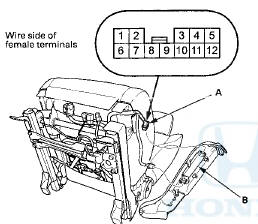

• 4-door (see page 20-234) • 2-door (see page 20-226) 3. Disconnect t h e 12P connector (A) from t h e p o w e r seat adjustment switch (B).

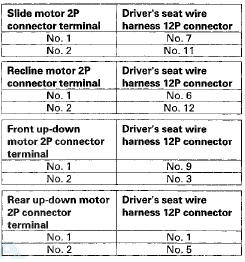

4. At the 12P connector of the driver's seat wire harness side, test the motor by applying battery power and ground to the terminals according to the table.

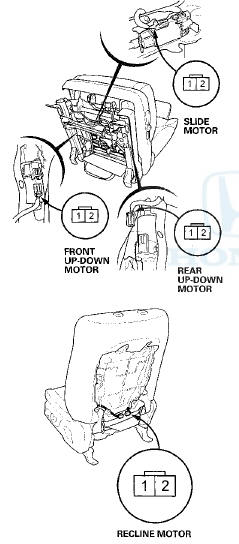

Slide motor

Recline motor

Front up-down motor

Rear up-down motor

5. If the motor does not run or fails to run smoothly, go to step 6.

6. Disconnect the 2P connector from each motor.

NOTE; • For the recline motor, remove the seat back panel.

- 4-door (see page 20-221) - 2-door (see page 20-213) • All connector views are wire side of female terminals.

7. Check for continuity between each motor 2P connector and the driver's seat wire harness 12P connector. If there is continuity, replace the appropriate motor: • Recline motor (see page 20-200) • Slide motor (see page 20-204) NOTE: The front and rear up-down motors are part of the up-down adjuster.

Power Seat Adjustment Switch

Test/Replacement

Power Seat Adjustment Switch

Test/Replacement

1. Remove the driver's seat (see page 20-194).

2. Remove the power seat adjustment switch knobs (A) and the recline cover from

the driver's seat.

• 4-door (see page 20-234)

• 2-door ...

See also:

Windshield Washers

Check the level in the windshield

washer reservoir at least monthly

during normal use.

Check the fluid level by removing

the cap and looking at the level

gauge.

On Canadian models: The low ...

Heating and Cooling System*/ClimateControl System* Maintenance

Dust and Pollen Filter

The heating and cooling system*/climate control system* is equipped with a

dust

and pollen filter that collects pollen, dust, and other debris in the air. The

Maintenance ...

Shift Cable Replacement

1. Remove the center console (see page 20-158).

2. Move the shift lever to R.

3. Remove the nut securing the shift cable end.

5. Rotate the socket holder retainer (A) counterclockwise

(B) ...