Honda Accord: Ball Joint Removal

Honda Accord: Ball Joint Removal

Special Tools Required

- Ball Joint Thread Protector, 14 mm 07AAE-SJAA100

- Ball Joint Thread Protector, 12 mm 07AAF-SDAA100

- Ball Joint Thread Protector, 10 mm 07AAF-SECA120

- Ball Joint Remover, 32 mm 07MAC-SL0A102

- Ball Joint Remover, 28 mm 07MAC-SL0A202

Always use a ball joint remover to disconnect a ball joint.

Do not strike the housing or any other part of the ball joint connection to disconnect it.

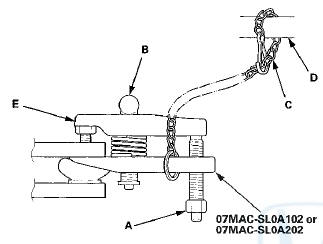

1. Install a hex nut (A) or the ball joint thread protector onto the threads of the ball joint (B).

2. Apply grease to the ball joint remover on the areas shown (A). This will ease the installation of the tool, and prevent damage to the pressure bolt (B) threads.

3. Loosen the pressure bolt (A), and install the ball joint remover as shown. Insert the jaws carefully, making sure not to damage the ball joint boot. Adjust the jaw spacing by turning the adjusting bolt (B).

NOTE: Fasten the safety chain (C) securely to a suspension arm or the subframe (D). Do not fasten it to a brake line or wire harness.

4. After adjusting the adjusting bolt, make sure the head of the adjusting bolt is in the position shown to allow the jaw (E) to pivot.

5. With a wrench, tighten the pressure bolt until the ball joint pin pops loose from the ball joint connecting hole. If necessary, apply penetrating type lubricant to loosen the ball joint pin.

NOTE: Do not use pneumatic or electric tools on the pressure bolt.

6. Remove the ball joint remover, then remove the nut or the ball joint thread protector from the end of the ball joint pin, and pull the ball joint out of the ball joint connecting hole. Inspect the ball joint boot, and replace it if damaged.

Wheel Bolt Replacement

Wheel Bolt Replacement

Special Tools Required

B a i l Joint Remover, 28 mm 07MAC-SL0A202

- Do not use a hammer or impact tools (pneumatic or

electric) to remove and install the wheel bolts.

- Be careful not to damag ...

Ball Joint Boot Inspection / Replacemen

Ball Joint Boot Inspection / Replacemen

Special Tools Required

- Clip Guide, 45 mm 070AG-SJA0300

-Clip Guide, 41 mm 07974-SA50700

1. Check the ball joint boot for weakness, damage,

cracks, and grease leaks.

NOTE:

- If the ball joint ...

See also:

Moonroof Control Unit input Test

NOTE; If the moonroof works OK manually, but will not work in AUTO, or

reverses frequently (obstacle detection), reset

the moonroof (see page 22-371) before proceeding with the input test

1. Turn ...

Clutch

...

Rear Seat Armrest Replacement

Special Tools Required

KTC Trim Tool Set SOJATP2014*

*Available through the Honda Tool and

Equipment

Program; call 888-424-6857

4-door

NOTE:

- Use the appropriate tool from the KTC trim tool s ...